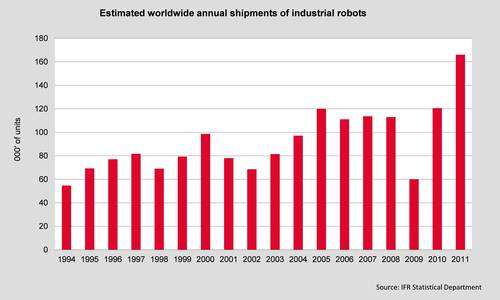

In 2011 sales of robots reached 166,028 units, an increase of 38% with the automotive industry the biggest purchaser. That year it was estimated that the world’s operational robot population reached somewhere between 1,153,000 and 1,400,000. That number was expected to grow by 180,000 in 2012, and increase to over 200,000 per year by 2015.

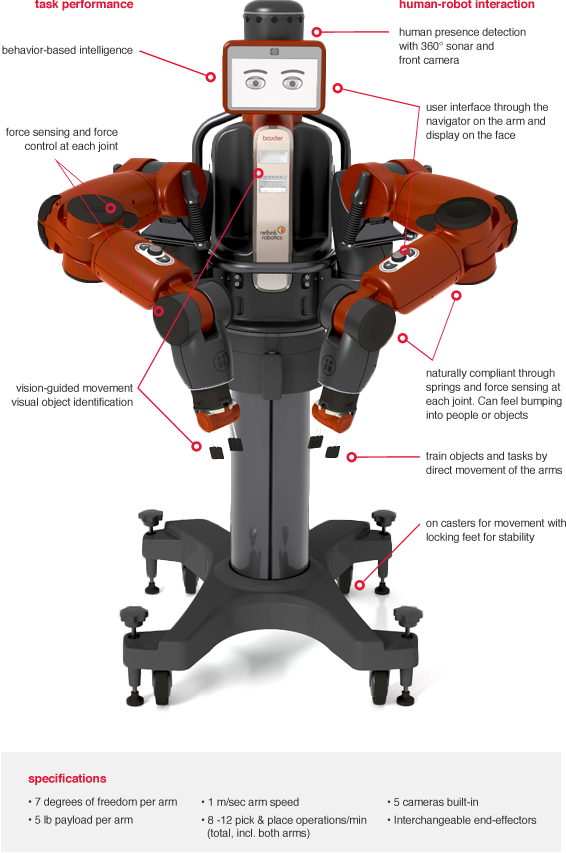

The industrial robots in these statistics cost six figures. But a Boston manufacturer, Rethink Robotics, has introduced a robot capable of performing a wide variety of common, repetitive tasks in the workplace at a fraction of the cost of previous manufacturers. Weighing 75 kilograms (165 pounds), standing 1.8 meters (6 feet), and known as Baxter, this is the first of a new generation of industrial robots that exhibits adaptive skills. Baxter, in a couple of minutes, can be programmed by almost anyone to accomplish new tasks. And unlike other industrial robots Baxter is very affordable at $22,000 U.S.

This is truly disruptive technology. Baxter is designed to do small-scale repetitive applications. Baxter can work beside humans in a facility without extra safeguards. Baxter interacts with humans through its LCD display which features eyes and eyebrows that express emotion. That same graphical display serves as an interactive console for human coworkers to reprogram Baxter. By showing Baxter what to do through manipulating his arms, a human worker can train it to do a new task. No software engineers need apply.

Out-of-the-box Baxter is pre-programmed to perform a wide range of manufacturing jobs including operating machines, materials handling, production line loading, unloading, assembly, finishing, inspecting, testing and sorting. In less than an hour Baxter can be on the job. And Baxter automatically alters its behaviour in response to any environmental change such as production line speed ups or variations in parts placement on an assembly line. Baxter can also adjust when a part is missed or dropped, or the assembly line surface height changes.

Baxter has no sharp edges or grippers that can inadvertently trap a human coworker. Baxter’s arms move fluidly and easily. Packed with sensors, Baxter can detect human presence nearby and avoid contact or reduce the force of any inadvertent collision.

Baxter as you can see in the image below comes with a mobile pedestal that allows it to be moved easily to different locations in a manufacturing facility. Its two interchangeable grippers can be switched in minutes. The electric parallel gripper features interchangeable fingers of different lengths with multiple grasp widths. The vacuum cup gripper comes with variable cup sizes and is used for hard-to-grasp objects.

In addition Baxter works with manufacturer enhancements from third parties and in 2013 will include a software development kit so users and re-marketers can reprogram the robot for unique tasks.

Baxter’s built-in smarts allow it to work in a number of industries including:

- rubber and plastics

- metal fabrication

- automotive assembly

- food processing

- consumer goods

Will deployment of Baxter in small manufacturing cost hundreds of thousands of jobs? Not according to Rodney Brooks, Chairman and Chief Technology Officer at Rethink Robotics. What it has the potential to do is lower the cost of small manufacturing so that it can be competitive with manufacturing overseas. That can impact hundreds of thousands of companies worldwide. And robots like Baxter will make an increasingly smaller workforce more productive as our population ages and the current generation of Baby Boom workers retire.

Robotics has always been an area of great expectations…..! It has always been a matter of time for robotics to move from large scale production lines to small manufacturing and ultimately domestic environments. I concur that Baxter and similar solutions will impact productivity of smaller entreprises. I, however, also share the line of thinking that robotics and automation in general will be a strong answer to low cost (manual) production.

The cost of labour in China at $1.25/hour adds up to an annual “labor” cost of $3,125. That means for break even analysis Baxter would probably have to serve its owners for 7-years to break even in comparison. Any manufactured product that lacks sufficient scale to justify production in China seems to fall into the category of “cottage industry.” These industries, in my opinion, are unlikely to sink $22,000 into a Baxter. Government contracts that stipulate domestic labor are what will pay for Baxters. In other words, Baxter seems to be just another burden on the increasingly unemployable hominid taxpayer.

How many hours does it take a Baxter to build a Baxter?

Good question. I’ll try and find out.

Niccolo asks: “How many hours does it take a Baxter to build a Baxter?”

Len answers: “Good question. I’ll try and find out.”

Niccolo asks: If a Baxter actually is significantly more productive per unit of cost than “human” labor, why would the Baxter-makers be selling their Baxters? Why wouldn’t they just lease their Baxters at prices, say 30%, below local labor market rates? That would seem to be the economic model that allows for most rapid growth and ever-increasing cash flow while avoiding dilution of control and ownership. Factoring or borrowing against existing Baxter “labor lease” contracts would seem to be a “no brainer.” Cash flow financing would be much easier for a single large business robot maker than for the multitudes of small business robot leasers. The large robot leasing business dilutes its risks over many different enterprises and counter parties, whereas the small business has all its eggs in one small vulnerable basket. Well, that is unless a Baxter just isn’t actually as productive as a natural born hominid robot. If Baxters actually are more productive than hominid labor, we shouldn’t have to wait long before we can rent them at Home Depot and United Rent-All or directly from the Baxter maker.

The public fact that Baxter has an advertised selling price suggests it will prove very challenging to ever get enough production out of a Baxter to pay for, or replicate, itself. When we can purchase or lease a “breeding pair” of Baxters that can build “offspring Baxters” at costs below initially buying or leasing Baxters from the Baxter Manufacturing Company, we will know the tireless mechanical robot worker has finally arrived. China, with its general indifference to patent and intellectual property rights, will be among the first places where Baxters would be programmed for self-replication. Legal protection against replication would be impossible. China’s government is still very much convinced that natural born self-replicating organic robots are more productive than mechanical robots. That might not be the case a decade hence.

Still, it seems the cost of mechanical robot brains and sensory systems are plummeting while performance is increasing exponentially. It’s just a matter of time before more advanced models of Baxters will be building more advanced models of Baxters that will prove more productive than market-priced organic labor.

[…] collaborative tools such as Rethink Robotic’s Baxter and Sawyer represent great examples of where this technology is heading for industrial and […]