January 1, 2017 – A number of years ago because of advancing osteoarthritis I was told I was a candidate for knee replacement surgery. Having lived with an arthritic left knee for most of my adult life, the stress on the joint has frequently caused problems including a ligament tear and sprains. But I am reluctant to consider switching out one of my natural body parts for a prosthetic replacement.

Why? Because I have talked to a number of people who have had knee replacement surgery and the procedure and recovery stories vary widely. Some have reported a full restoration of mobility after several months of rehabilitation. Others have had to undergo more than one knee replacement within a decade. In fact, one of my very good friends who had knee replacement done over a year ago informed me that the government issued prosthetic that cost nothing in Canada’s public health plan had a 50% failure rate after ten years. So for his surgery he was paying extra to get the good knee prosthetic.

I have researched non-surgical treatments from cortisone and hyaluronic acid injections, to platelet and experimental stem cell treatments to regrow cartilage in the knee joint. Currently I am receiving cortisone injections every three to four months. The injections have produced significant pain relief and given me increased mobility including the ability to walk up and down stairs more easily and without discomfort. But there may be a technology solution that could get me to reconsider a knee prosthetic.

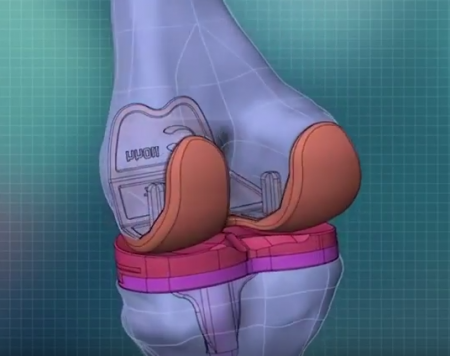

It involves the 3D printing of custom-made knee joints. 3D printing is being used today to create blood vessels, ears and other body parts. But this is the first time that I have read of its use in knee and hip replacement.

Where is it being done? In Denver Colorado, Dr. Ian Dickey, at Presbyterian St. Luke’s Medical Center, is pioneering the technology. In a YouTube video he describes why 3D printing produces better outcomes. The process begins with a CT scan of the effected limb, not just the hip or knee joint.

Why the entire limb? Because the goal is to restore perfect alignment to the limb after repair. With a CT image software can produce a 3D rendering of the joint and limb. The 3D image provides X, Y and Z coordinates for the joint. These get used to create a modeled joint that can make corrections to the alignment producing an implant with the correct thickness and width. The information gets fed to the 3D printer to create an implant that is precise to one-thousandth of a millimeter.

When you consider that 5% of the 600,000 knee replacements performed in the United States and 60,000 in Canada represent repairs to already replaced knees, custom-designed prosthetics could eliminate 33,000 procedures annually. The average non-custom knee prosthetic today has a life between 15 to 20 years before wear, loosening, infection, fracture, instability or stiffness and pain create the need for replacement. With rising obesity rates in both countries, knee and hip surgery procedures are expected to increase 15% annually. Doctors advise patients that one of the best ways to decrease knee and hip joint replacement is to keep body weight down.