At the University of New South Wales (UNSW) in Sydney, Australia, engineers have invented a tiny, flexible, and soft robotic arm to 3D print biomaterial inside a human body. The field of bioprinting has just seen an innovation that will take it out of the laboratory and into the operatory.

The robotic arm was developed at UNSW’s Medical Robotics Lab under the supervision of Dr. Thanh Nho Do, a Scientia Senior Lecturer in the Graduate School of Biomedical Engineering, Mai Thank Thai, one of his Ph.D. students, and other UNSW staff. They recently published their research in the journal of Advanced Science.

Bioprinters up until now have tended to be large desktop printers. Creating living constructs, therefore, has been done outside the body. That means transporting the finished print job to the operatory and then inserting it into a host. This method can lead to many things going wrong. The finished print may not fit where it is intended to go. The threat of contamination is real. And during transport, the bioprinted material could be damaged.

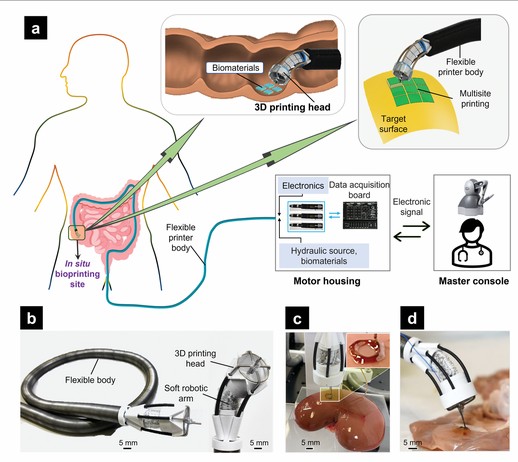

The UNSW team decided that a better approach would be to do bioprinting inside a living body. So they created a proof-of-concept 3D bioprinter called the F3DB. It features a flexible robotic arm, a soft printing head, and software based on a kinematic inversion model and machine-learning-based controllers.

This bioprinter is intended to be a model for the future development of endoscopic surgical robots to allow for minimally-invasive procedures to be used to repair tissue damage from disease, trauma, and injury. How soon will this go from concept to common usage?

The team sees with further improvements to the F3DB, such as an integrated camera and real-time scanning to create 3D tomography, its successors within the next five years will be used by medical teams to do minimally invasive procedures to go to places hard to reach to make necessary repairs.

The team has demonstrated the F3DB using a variety of shaped biomaterials in an artificial colon as well as on a pig kidney. Their experiments did no damage to living cells which continued to grow after usage.

In a UNSW press release, Dr. Do states, “This system offers the potential for the precise reconstruction of three-dimensional wounds inside the body, such as gastric wall injuries or damage and disease inside the colon.”

He continues, describing the F3DB as “able to 3D print multilayered biomaterials of different sizes and shape…thanks to its flexible body.”

How big is the F3DB proof-of-concept? It is similar in size to commercial therapeutic endoscopes used today for gastroscopies and endoscopies. But the team believes it can be made even smaller for future applications.

The F3DB features:

- a three-axis printing head mounted on the tip of a soft robotic arm that can be configured to print pre-determined shapes, or can be operated manually for custom print jobs.

- a head that consists of soft artificial muscles allowing it to move in three directions.

- an ability to bend and twist using built-in hydraulics.

- a nozzle in the head that can direct water that can clean blood and excess tissue from the site where the biomaterial is implanted. The nozzle can also act like an electric scalpel to cut away cancerous lesions and other damaged tissue to create a clean field for applying the living bioprinted material.

- the use of a variety of materials to construct it to variable lengths and stiffness depending upon the application.