January 5, 2016 – The world of 3D printing has been moving from hobbyist, one-off production using plastics and resins as “inks” to industrial materials. NASA and SpaceX have demonstrated 3D printing of rocket motor components that in testing have met the toughest standards for heat and cold tolerance, important for components exposed to outer space and getting there.

The latest innovation uses a polymer resin “ink” to print customized ceramic parts and components for use in complex manufacturing. HRL Laboratories, LLC, announced this week that they had achieved a new breakthrough, “an approach to additive manufacture ceramics that overcomes the limits of traditional ceramic processing and enables high temperature, high strength ceramic components.” HRL has published its technology findings in the January 1, 2016 edition of the journal Science. HRL states that the challenge in using ceramics in additive manufacturing is that “ceramics cannot be cast or machined easily” unlike polymers and metals.

So how is HRL managing to produce finished ceramics using 3D printing?

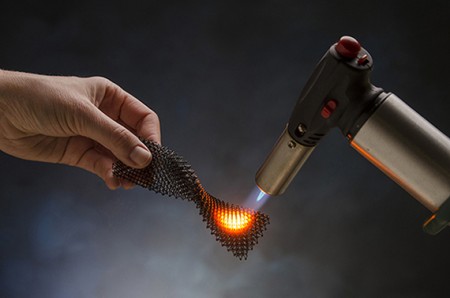

They have invented a printable resin made from pre-ceramic polymers. They then use stereo lithography to construct structures layer by layer. They have demonstrated using laser beams and ultraviolet light guidance, the polymer resin and stereo lithography with a 3D printer an ability to build complex structures at rates 100 to 1,000 times faster than conventional manufacturing with stereo lithography. The finished products are then cooked in a kiln at temperatures exceeding 1,700 degrees Celsius (3,100 Fahrenheit) which overnight converts the resin to a high quality ceramic.

What are the kinds of 3D-printed products that this technology can produce?

- heat-resistant, lightweight, exterior panels and surfaces for spacecraft and airplanes.

- heat resistant internal components within jet and rocket engines.

- intricate sub-components for use in microelectronics and electromechanical devices.

The potential high density lattices produced using HRL’s techniques provide an alternative to today’s ceramic foams such as the material used to produce the heat shield for the Space Shuttle. Consisting of thousands of individually custom crafted ceramic foam tiles, over several flights the material proved extremely fragile when exposed to the stresses of launch, spaceflight and re-entry. Between missions a big cost component in the refit of the Space Shuttle fleet was the replacement of thousands of these tiles.

With the technology developed by HRL, new ceramic lattices and foams can be 10 times stronger than current commercial products. Ceramic lattices aren’t meant to be load bearing but with the added strength of HRL’s new method and material, parts created should prove to be far more durable and a key advancement for a space industry going through a paradigm shift to reusability.