Researchers at Nanjing University in China have invented a nanocellulose aerogel film that can keep things wrapped in it cool. The cellulose aerogel causes radiative cooling. If not familiar with that term, it is a phenomenon one can observe on a cloudy day. Cities today are experimenting with white roofs and painting street and parking lot surfaces with highly reflective white or light blue paint.

The dust-resistant, hydrophobic, nanocellulose aerogel is eco-friendly and offers a highly effective passive cooling system. Chenyang Cai, Associate Professor in the College of Material Science and Engineering at Nanjing, recently told Newswise:

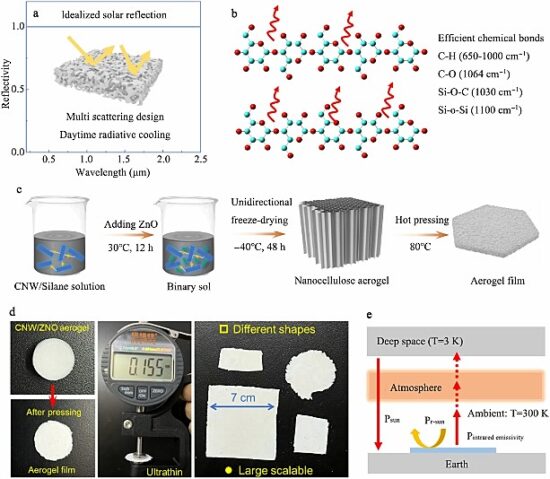

“The scalability of the nanocellulose aerogel film is achieved through freeze-drying and hot-pressing techniques. This pioneering cellulosic cooling solution can deliver a sub-ambient temperature reduction of 6.9 Celsius [12.4 Fahrenheit] under direct sunlight in hot conditions while also exhibiting dust-repellent properties.”

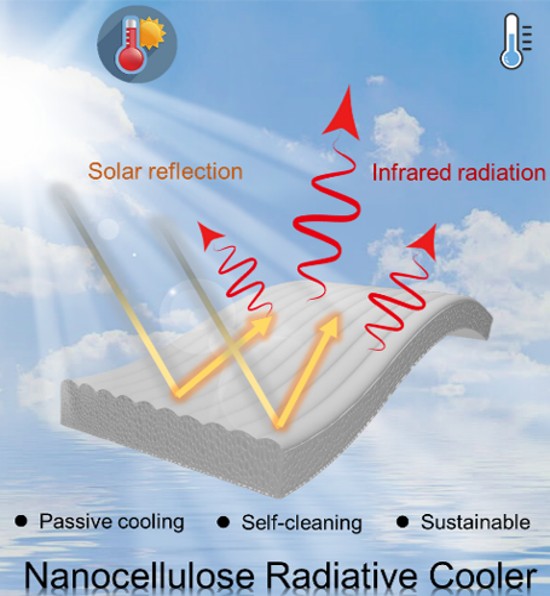

The following illustration shows how the material works.

Conventional heating and air conditioning (HVAC) systems need an external energy supply to do space cooling. Passive radiative cooling does not. Instead, the heat source falling on the object gets bounced back into the atmosphere and space.

When you consider that global warming is expected to raise atmospheric temperatures several degrees Celsius before the end of the century, the use of this aerogel film as a passive cooling system could help buildings reduce the absorption of heat and infrared radiation during hot summer days.

When you think cellulose, you may immediately associate it with the transparent material used today to wrap foods and leftovers put in refrigerators. That’s not what the researchers saw.

They looked at cellulose’s chemical bonds which provide highly desirable radiative cooling properties. They also noted that cellulose produced from non-petroleum sources was widely abundant because it can be harvested from trees. They also knew they had to overcome two existing cellulose-based film drawbacks:

- Poor sunlight reflective capacity.

- Airborne dust interference.

The Nanjing research team, therefore, chose to use zinc oxide added to harvested cellulose fibres to make the composite aerogel film. The zinc oxide regulated the optical and structural properties of the fibres producing an aerogel film with 97% solar reflectance, 92.5% high infrared emittance, and excellent hydrophobicity properties.

Where ordinary cellulose film is transparent, the nanocellulose aerogel film they produced was not.

Where ordinary cellulose film is smooth, the aerogel film produced has rough surfaces that keep dust and water away.

The result is a practical material that provides sustainable passive radiative properties. It can be a building wrapper creating comfortable internal environments regardless of how hot it is outside.

It doesn’t need an external energy source to provide cooling which makes it an ideal climate change adaptive technology.

And because it lessens energy demand, it means we don’t have to produce it with greenhouse gas emission pollutants making it harder for climate change mitigation.

To learn more read the research article which appears in the Journal of Bioresources and Bioproducts this month.