In the pursuit of 100% electrification of the global economy, two recent advancements in battery technology caught my eye. The first is an improved recycling process for Lithium-ion (Li-ion) batteries from researchers at Rice University. The second is the development of a solid electrolyte for use in Lithium batteries developed at the University of Science and Technology of China (USTC).

New Battery Materials Recycling Process Invented

Recycling and reuse of Li-ion battery materials has been the focus of research for some time particularly when you consider the growing number of electric vehicle (EV) manufacturers and the public interest in making the switch to fossil-free transportation alternatives.

The best recycling methods for Li-ion to date involve shredding and thermal and chemical processes. A Canadian company, Li-Cycle claims its methodology recovers 95% of materials that go into Li-ion battery packs.

The researchers at Rice University believe they can do better and have invented a recycling process that exceeds 98%. James Tour, a Professor of Chemistry and Materials Science and Nanoengineering at Rice, in a July 24, 2024 news release states, “With the surge in battery use, particularly in EVs, the need for developing sustainable recycling methods is pressing.” Rice’s three-step method is called Flash Recycling (FR). It is solvent and water-free and involves the following:

- Flash Joule Heating (FJH) – a method of extracting rare earth elements using an electrical current that heats the battery to 2,727 Celsius (4,940 Fahrenheit°F) to begin the separation into distinct materials.

- Magnetic separation – a process that uses magnets to separate the cathode materials which are typically metal-based containing manganese, iron, cobalt and nickel from the carbon-based anode materials.

- Solid-state relithiation – a method that restores lithium’s electrochemical performance for use in new batteries.

Tour notes that the process retains the structure and functionality of the reconstituted materials for use in new cathodes. These materials represent the biggest cost in Li-ion battery production.

An article describing the research and methodology appeared in the journal Nature Communications on July 24, 2024.

Considering the vast majority of EVs on today’s roads use Li-ion battery packs, recycling and reuse will be much in demand.

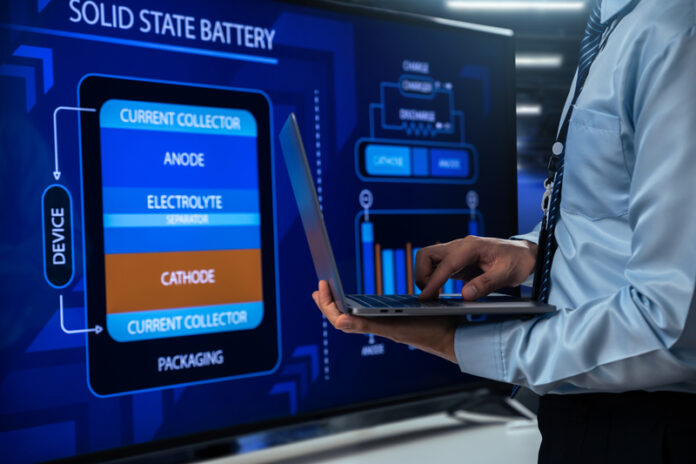

Lithium Solid-State Batteries One Step Closer To Reality

The EV battery legacy may be Li-ion liquid batteries, but the future is solid-state. Researchers at USTC have been pursuing this technology for some time to make a solid-state lithium battery that could make liquid-electrolyte-based battery packs obsolete.

Why develop solid-state lithium batteries when Li-ion technology today is almost everywhere? Solid-state batteries can punch the same amount of energy produced by current EV Li-ion liquid battery packs using smaller and lighter form factors. They also can be recharged faster. Weight reductions, faster recharge times, and greater range are good news to EV manufacturers.

Up until now, however, solid-state battery technology was costly. The USTC researchers believe their battery overcomes the cost issue. The battery electrolyte is called Li7P3S7.5O3.5 (LPSO) and costs US $14.42 per kilogram, well below what the EV battery industry has indicated is the $50 per kilogram threshold for commercialization.

Who else is doing solid-state battery research and development? The contenders include Toyota and Samsung who have announced target dates in 2027 for their first solid-state battery EVs. Others in the mix include Mercedes-Benz, General Motors, Ford and other Western automobile manufacturers. Where is Tesla, the leading EV car maker when talking about solid-state battery development? Elon Musk and Tesla so far are not interested.

Cheng Ma is one of the authors of an article that appeared in the German journal Angewandte Chemie, on June 30, 2024, that describes the USTC solid-state battery breakthrough. He describes the LPSO technology as having a lower energy density than sulphide solid electrolytes under development but notes performance improvements are expected soon. The battery through 200 recharge cycles retains energy capacity at 89.29%. When combined with lithium metal, the LPSO demonstrates an ability to maintain more than 4,200 hours of stable cycling at room temperatures.

China aims to be at the forefront of rechargeable battery technology and a well-established solid-state battery supply chain in place by 2030. This year the government launched the China All-Solid-State Battery Collaborative Innovation Platform to bring together government, academia and the country’s largest EV manufacturers, CATL and BYD. BYD already surpasses Tesla in unit sales. When the Chinese perfect solid-state batteries, will we all by the mid-2030s be driving “Made in China” EVs?