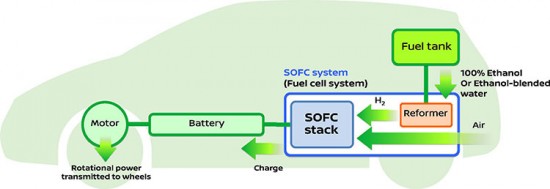

June 15, 2016 – Nissan Motor Company is building an electric vehicle (EV) that gets its juice from bioethanol which during combustion produces hydrogen as a byproduct. The exhaust heat drives the reaction. The hydrogen then feeds an e-Bio and Solid Oxide Fuel Cell (SOFC) which combines with oxygen drawn from ambient air to charge the vehicles’ batteries. That means no need for an oxidizer and as a result less weight.

SOFCs can use a range of fuel sources including ethanol and natural gas to initiate the generation of electricity. In the Nissan configuration the e-Bio component reforms an ethanol-water mix to create the hydrogen. The fuel can be sourced from corn, and sugar cane. And SOFCs are highly efficient power generators producing driving ranges equivalent to gasoline and diesel-engine cars. Nissan claims that a single bioethanol fill up will allow the car to travel up to 600 kilometers before a pit stop. Refueling is no more complicated than stopping at a local gas station.

Nissan believes that creating a bioethanol fuel delivery system should be relatively easy. The ethanol-water blend is much safer than gasoline or diesel and therefore easier to transport and store.

But if the car uses bioethanol isn’t carbon dioxide a byproduct of the combustion? Nissan points to the fuel source, corn and sugar cane, stating that these crops represent a carbon sink making the vehicle net carbon neutral.

The image seen below appears in the press release issued by Nissan.

If the company can work out the bugs, establish the fuel infrastructure, and scale up production, this technology could prove to be a real game changer. The company did not announce when it expected to deliver its first eBio-SOFC model.