Biomechanics is the biological equivalent of a human-computer duopoly. A duopoly is normally a marketing term describing a situation in which there are only two sellers. So I’m taking poetic license in using the term and doing so to describe what is both a convergence of humanity and machines as well as symbiosis.

In the world of biology, the human-machine duopoly can be equated with biomechanics and bioelectronics. When you think biomechanics think prosthetic devices. When you think bioelectronics think about imprintable circuits that can be applied to or injected into the body to monitor or assist in maintaining health. The two can be combined to make smart prosthetic devices. It will become harder and harder to separate the biological from the electromechanical.

Prosthetics

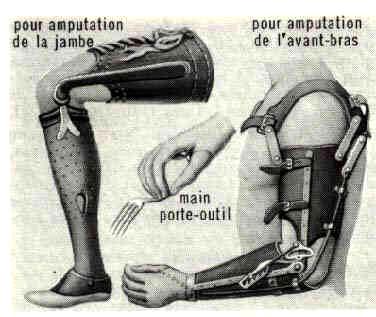

In times of war it seems we make the greatest advances in creating replacement parts for human limbs lost. We have been doing this as far back as 484 BCE. Herodotus in “The Histories” speaks of a Persian solder who replaced a severed foot with one made from wood. Other historic finds have dug up limbs made of copper later to be replaced in the Renaissance by iron prostheses. In the 16th century Ambroise Pare, a French surgeon invented both upper and lower body prosthetics. The arm prosthetic featured a hand-operated by springs while the leg included an articulated knee joint.

Pare is known for a number of other battlefield innovations including ligatures, field bandages, and surgical instruments that were the precursors to those used today in operating rooms.

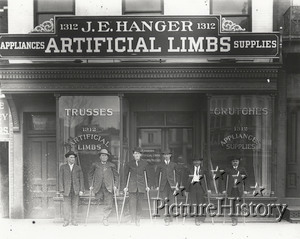

The American Civil War led to surgical advances and experimentation with prostheses. Chloroform as an anesthetic made it possible for surgeons to amputate and prepare leg and arm stumps to better fit prosthetic replacements. The first documented amputee of that war, James Edward Hanger, was so dissatisfied by the prosthetic wooden leg he received after losing his to a Union cannonball, that he designed and constructed a new one from barrel staves, rubber and wood creating hinges at the knee and foot. Soon after Hanger was awarded a patent for his artificial limb.

Today Hanger Prosthetics and Orthotics is a major manufacturer of artificial replacement parts for humans and even dolphins.

In World War 1 prostheses didn’t just replace lost limbs. Soldiers who suffered from facial disfigurements received lightweight metal and rubber replacements that were often painted while being worn to match skin colouring. War veterans could buy prosthetic limbs advertised in local newspapers. Prostheses made from lightweight metals such as aluminum prevailed replacing wood, iron and steel. World War 2 saw the introduction of plastics and glass fibres. Post war research led to the development of mechanical arms with hooked ends that could be opened or closed using shoulder muscles. The Vietnam War inspired further advances in replacing lost limbs introducing electronic controls.

Our ingenuity to replace damaged body parts goes well beyond appendages and face masks. Cosmetic prosthetics have included dentures to replace decayed teeth and artificial eyes. Unlike dentures which served adequately to replace teeth, artificial eyes could not replace eyesight, at least not until recently.

Bionics: More than Just artificial Arms and Legs

In 1974 American television was introduced to Steve Austin, The Six Million Dollar Man, a test pilot and astronaut who after an accident was transformed into a fusion of human and machine. Austin may have been a fictional creation but the science of bionics is very real with the creation of artificial systems to replace natural ones. Our sensory organs, in particular the ear has been subject to all kinds of bioengineering inventiveness.

Today, of all our senses, we have made the greatest advances in creating artificially assisted hearing. From Alexander Graham Bell’s earliest forays to the era of the transistor and computer chip making it possible for wearable hearing aids, the technology largely focused on creating amplified sound. Hearing aids have gotten progressively smaller and more capable in dealing with sound quality and background noise cancellation. But essentially none of these devices are capable of helping humans who are totally deaf.

The advent of the cochlear implant, a prosthetic device designed to compensate for sensorineural hearing loss, represents a major technological advance in prosthetic technology. The first attempts at implantable hearing devices date back to 1961. In 1984 commercial versions of cochlear implants became available for surgical implantation.

The device connects directly to the auditory nerve, bypassing the inner ear. Part of the device containing a receiver, a magnet, wires and an electrode array, is implanted subcutaneously. A digital signal processor with cable and microphone are placed externally in the area of the ear. The external microphone picks up sound which is converted to an electrical current by the digital signal processor . The electrical signal is transmitted to the subcutaneous receiver which then sends the signal to the inner ear auditory nerve fibres which pass them along to the sound receptors in the brain. Advances in digital signal processing technology will further improve cochlear implants leading to better speech processing and greater range of discrimination in sound frequencies.

Touch Bionics is a company developing fully articulated myoelectric prosthetic devices. Fully articulated myoelectric means the prosthetic is active, capable of a range of functionality that approximates a natural limb or appendage including very fine dexterity. The company has developed the i-limb(TM) ultra with biosim control software. With this prosthetic hand the wearer can type, pinch, grip objects from marbles to eggs, apply variable pressure, shake hands, and tie shoelaces. The hand works by picking up signals from electrodes placed on the surface of the associated arm and translating those to the prosthetic. Software lets the wearer further customize the range of activities, monitor myoelectric impulses and do training.

Retooling the Human Body: Imprinting, Biosensors, Bioelectronics and Implants

We started pacing the heart with implantable devices in 1958. With the shrinking of transistors, the development of integrated circuits and now micro-circuitry at an atomic level we are marrying electronics and biology to work together.

Imprintables

Researchers at the University of Illinois have developed electronic devices to imprint on skin as temporary tattoos. These sensory devices work unobtrusively recording medical vital signs. Each device is protected by a rubbery silicone film and stretches with the skin. The electronics includes light-emitting diodes, solar cells for autonomous power, transistors and wireless connectivity to uplink data to a monitoring computer. A sensor can be programmed to pick up heartbeats, muscle activity and brainwaves. It can also be used as a computer controller making it useful for studying body movement. Some have even suggested its use as a game controller.

Implantables

Implanting a skin sensor is one thing. What about implanting a device that combines biological and artificial materials to become part of a person’s body. These 21st century inventions will include devices like heart valves that grow with the child, or artificial ears, and eyes. We’ll talk more about implantables when we explore nanotechnology in biomedicine in a future blog.

Biosensors, Bioelectronics

Biosensors are devices that incorporate biological or biologically mimicking materials such as engineered proteins or synthetic receptors. This is technology at an atomic scale. Such devices integrate microsystems technology using a variety of energy sources to provide power. For example, a biosensor with bioelectronics could use the chemistry of the bloodstream or its fluid dynamics to allow it to steer and manoeuvre through the body. Or it could be accompanied by a biological fuel cell and navigate autonomously. Biosensors are designed to broadcast to a receiver and can be used to monitor all kinds of vital body activity.

Currently biosensors are being used to study DNA and protein in cells. Future application of this technology include better methods for measuring biological systems. Here are near future applications for the convergence of humans and machines at a micro level:

- Artificial pancreas to regenerate insulin production in the body and end diabetes

- Neural implants to correct loss of vision and hearing

- Medical drug and sera delivery systems for disease prevention or for curing an existing condition

- Repair of spinal cord or brain injuries through neuron repair or implantable nerve chips

- A lab-on-a-chip for continuous monitoring of vital functions

The National Institute of Standards and Technology (NIST) roadmap for biosensor and bioelectronic development sees much of this happening before 2030.