February 16, 2015 – Magna Parva, of Leicester, England, is in the design and build business. The company focuses on research and development projects for science, medicine, energy, defence and space. Its latest announcement is focused on the latter – building big structures in outer space.

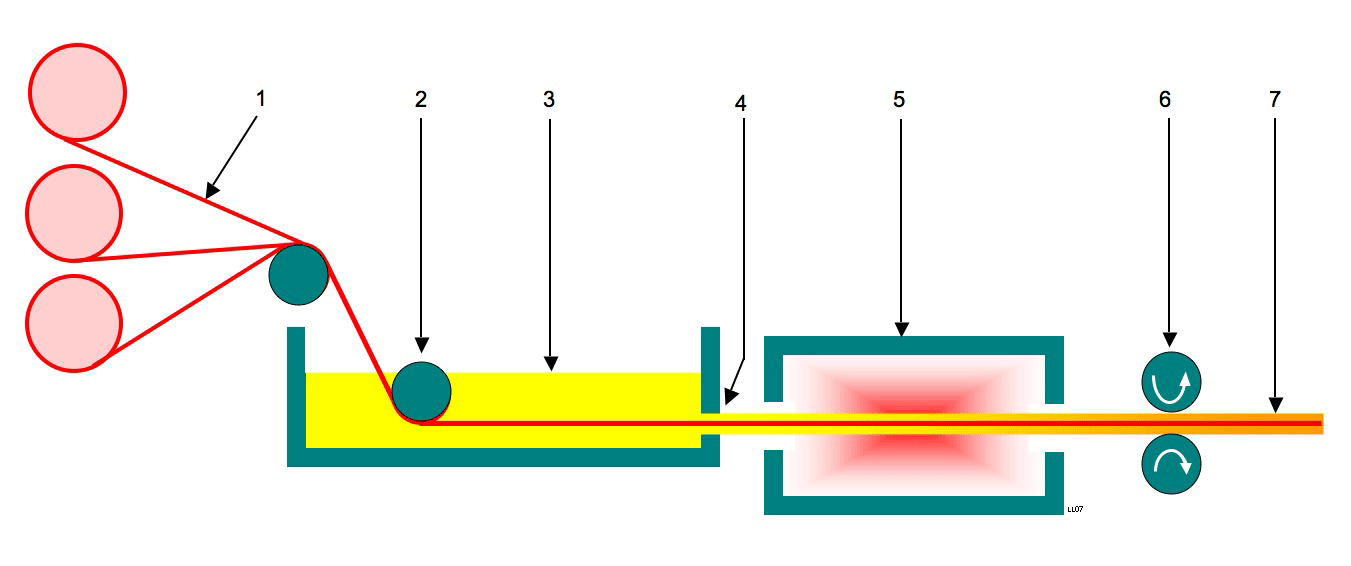

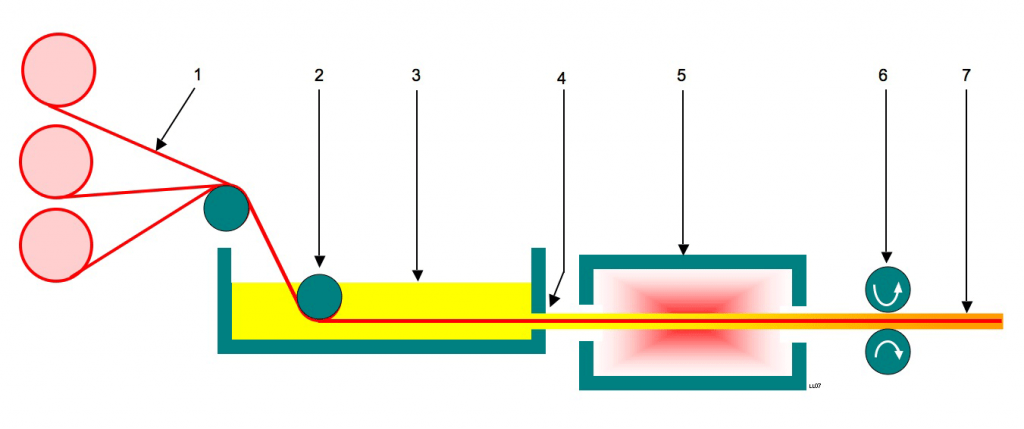

The method of manufacturing is called pultrusion. The technology is a continuous molding process whereby construction materials are formed and pulled through a heated die to form the kind of parts needed if humans are to build Deep Space habitations or colonies on the lunar or Martian surface.

For space antennas or spars needed to create the honeycomb lattices used by structures like the International Space Station, pultrusion could prove to be a disruptive game breaker.

Just how big can one of these structures be? Lengths of 200 meters (660 feet) can be created in situ. In an article appearing in yesterday’s Financial Times, Magna Parva’s co-founder, Andy Bowyer is quoted stating: “Everyone wants big stuff in space but they can’t have it at the moment. Our technology would enable that to happen.”

This goes one step beyond the 3D-printing technology currently being tested on the International Space Station. That technology as deployed is good for the small stuff. But pultrusion technology can build the really big structures needed for human space and off-world habitats and satellites.

Today you can find pultrusion used here on Earth to build glass fibers used in fiber optics. But what Magna Parva is proposing is to bring the manufacturing technology to space. Working with the European Space Agency currently on a number of projects, the company is proposing to demonstrate this capability on future space missions.

Is pultrusion manufacturing something new? Or have we seen this suggested before?

Back in 1987 a number of NASA scientists collaborated on a paper in which they described a method of reducing the amount of material to be lifted into orbit to lower the cost of space structures. It was pultrusion. The paper described a process using pre-impregnated graphite-fiber combined with thermoplastic resin coiled in spools. These would be stored in payloads and transported into orbit. Along with the materials would come a pultrusion system designed to fabricate desired structures including honeycombs, lattices, I-beams, spars and other linear designs. The authors of the paper calculated that pultrusion in-orbit manufacturing would reduce payload volumes by 56%, accelerating the ability to construct significant space infrastructure. Somehow or other the proposal never led to funding a prototype or test.

With this latest Magna Parva announcement it appears that what NASA scientists once proposed will finally become a reality altering the nature of the way we build in space and significantly lowering the cost.

[…] British Company Has Plans to Manufacture Big Structures in Space https://www.21stcentech.com/british-company-plans-manufacture.….res-space/ […]