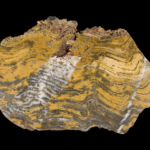

May 22, 2014 – What is holding back wider adoption of electric vehicles (EVs)? The power and mileage limits of the battery and recharge speed. These are the limitations of lithium-ion technology found in every EV on the road today. But that may come to an end if the battery (seen in the image below) developed by Power Japan Plus is mass produced.

It doesn’t look like much but this battery is a disruptor with considerable potential. It’s called the Ryden dual carbon battery. It has the same energy density as lithium-ion but is made of carbon. The company is even making the battery materials from what it calls organic carbon.

The Ryden carbon battery charges 20 times faster than lithium-ion and is rated for more than 3,000 charge and discharge cycles. Compare that to lithium-ion which in the case of the Tesla Model S sedan is rated to be good for up to 1,500 charge and discharge cycles.

The Ryden carbon battery doesn’t overheat. That can’t be said for lithium-ion although incidence of abnormal heating and fire have been rare.

The Ryden carbon battery contains no rare earth or heavy metals. Every lithium-ion battery in an EV contains 1 kilogram (2.2 pounds) of rare earth metals.

The Ryden carbon battery is 100% recyclable. Today we are just beginning to develop battery-recycling for EVs. That’s because very few have reached end-of-life usage to warrant the need. And although most components in current lithium-ion batteries can be recycled the process for recovering the heavy metals and other materials requires specialized plants.

Japan Power Plus plans to manufacture 18,650 Ryden batteries this year with biomedical and space science customers already lined up. For EVs the company intends to license the technology to manufacturers.

The Ryden carbon battery was developed at Kyushu University in Japan, the same designers involved in the batteries found today in the Toyota Prius and the Tesla Model S. So it would seem that these folks know what they’re doing.

With Tesla planning to build a massive battery manufacturing facility in the United States, it may be prudent for the company to consider this new battery for production. Do I hear Elon Musk picking up the phone to make a call?

((What is holding back wider adoption of electric vehicles (EVs)? The power and mileage limits of the battery and recharge speed. These are the limitations of lithium-ion technology found in every EV on the road today. But that may come to an end if the battery (seen in the image below) developed by Power Japan Plus is mass produced.))

I agree these are all important factors, but I don’t think they are the main factor. Take for example the $32,000 current model Chevy Volt. For the major part of the electric car market, the Volt seems the best balance of features and costs. Its principle technical limitation is it’s battery-only range, which is about 30 miles. Then the ICE starts up and the vehicle burns gasoline for the next couple hundred miles until more gasoline is supplied or until the battery is plugged in for a four-hour recharge. In effect it’s a smooth quiet gasoline vehicle that gets about 40-mpg. It’s pretty much the same car as a Chevy Cruz, except it costs $14,000 more. But if you aren’t going more than 30 miles before you return home it gets about 1000 miles per gallon of fuel. Every time a Volt driver plugs in his Volt he saves the cost of about ½ gallon of gasoline. Say $1.75. In effect he is paying himself $1.75 for every 30-mile trip he takes. But in order to get that job he had to pay the extra purchase cost of $14,000. Is a job that pays $350 per year for a few minutes of work per day worth $14,000? I’m guessing most motorists can do the math, and figure it’s a bad deal.

So the question is what utility would the average motorist actually get for the $14,000? If the Volt sold for the same money, and its battery were three times larger, the $14,000 would buy a 90-mile range electric car. There is a huge difference in the practical utility of 90-mile range vs. 30-mile range. The real issue is not battery performance per pound or recharge time or more efficient regenerative braking. The real issue is battery cost per KWh stored and discharged. GM developed the Volt with the hopes that battery costs would fall dramatically, and the electric car market would explode with GM way at the head of the pack. A 90-mile round trip range with 3000 charge cycles for the same $14,000 extra cost, would likely expand the Volt market 20-fold.

The carbon battery sounds too good to be true, and I suspect that it is. The real issue is how much cheaper is it than present batteries? Seems a real waste of advanced technology to put the magic carbon battery in a car. Why not just replace the utility power plants and distribution grids with solar cells and carbon batteries at every residence? I couldn’t help noticing that the promotional material focused on telling us magic batteries would be much better than conventional batteries, but was very stingy in supplying technical details or a demonstration of melting a garbage pail of crushed ice.