October 28, 2018 – Canada’s federal government has put a payment down on fusion reaction investing almost $50 million in General Fusion, a Burnaby, British Columbia clean technology company. General Fusion was founded in 2002 with its mission to create the first cost-competitive, commercial fusion power plant.

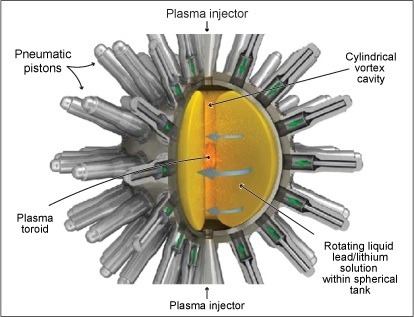

The technology it is developing is called Magnetized Target Fusion (MTF) using a liquid lead-lithium vortex contained within a spherical chamber which is then injected with a magnetically-confined plasma pulse. An array of pistons on the exterior of the sphere then drive up the pressure within it to confine the plasma to a point where fusion occurs. The heat created from the reaction is transferred to the liquid lead-lithium and then harvested using a heat exchanger to power a steam turbine.

In many respects, General Fusion’s approach to creating power from generated heat is quite conventional bearing a strong resemblance to the back-end technology found at natural gas, coal, and other thermal generation plants. But it is the use of the liquid metal within the chamber, the source of the heat used to create electrical energy that is unconventional. The lead-lithium liquid protects the sphere’s outer wall and can be pumped to heat exchangers and then recycled.

The exterior pistons are not new technology. And the fusion fuel, magnetized plasma requires no manufacturing to produce. Electricity generated also uses conventional technology. General Fusion’s technology is modular allowing a single utility-run power plant to employ multiple units. Or it can be used as a local micro-grid power source within a city or on an industrial site.

An MTF system differs considerably from other fusion energy systems under development. Because it uses pneumatic pistons to compress the plasma it reduces the energy needed to create fusion and producing positive energy yields that are equal to or better than conventional thermal power plant technology.

So what are the details? Starting with a high-strength metal sphere about three meters in diameter, liquid lead-lithium is then injected into it to fill it. The liquid metal is then spun which creates a central cavity within the sphere. The plasma which is injected into the cavity is composed of deuterium-tritium. The pneumatic pistons use compressed gas to accelerate to 50 meters per second. This creates spherical compression in the liquid metal forming a shock wave that results in fusion at the core of the cavity. The energy derived from the fusion releases as fast neutrons which are slowed down when they strike the spinning liquid metal. The energy of the neutrons gets converted to heat which through a heat exchanger provides the energy to operate a standard steam turbine. The cycled steam also serves to continue to drive the pistons repeating the fusion cycle at a rate of about one time per second.

The energy produced is ten times greater than the required input needed to create it. Compare that to ITER, the multi-billion dollar fusion project being built in France that has yet to produce a surplus megawatt of energy.