As Canada’s Pathway Alliance continues to talk but not walk the walk about its proposed carbon dioxide (CO2) capture and storage network pipeline project in Alberta, others are investing in “real” solutions with some already in operation.

The Alliance was first announced in 2021 and involves Canada’s largest oil sand producers: Canadian Natural Resources, Cenovus Energy, Imperial Oil (a subsidiary of Exxon-Mobil), MEG Energy, and Suncor Energy. A visit to the website tells you all you need to know about the current status of this project.

Others, however, are stepping up with technology designed to reduce and capture CO2 emissions from existing projects or grab the greenhouse gas directly from the atmosphere.

Shell Canada Announces The Polaris CCS Project

Shell Canada has operated the Quest carbon capture and storage (CCS) facility at its Scotford, Alberta plant since 2015. So far it claims to have captured over 9 million tons of CO2 from the site.

On June 26, 2024, it announced a new project called Polaris to be added at Scotford to sequester an additional 650,000 tons of CO2 annually. It should be operational at the end of 2028.

When Quest was first envisioned, its designers stated with optimism that it was readily reproducible and could be brought in at a fraction of the cost for future CCS projects. Now we shall see if this is true.

For CCS to be a valuable tool in mitigating climate change, the cost of capturing the greenhouse gas per ton has to come down. Companies like Shell need to take on the burden and responsibility of making the technology viable while at the same time, ramping down fossil fuel production this decade and beyond to ensure the global economy moves from oil and gas to electricity for energy and transportation.

Occidental Investment In Direct Air Capture of CO2

Shell has been joined by Occidental Petroleum, the American fossil fuel company, in making real investments to capture CO2. Occidental acquired Carbon Engineering in August 2023, a Canadian-based direct air capture (DAC) company. The technology harvests CO2 from the air. It can be built to operate anywhere.

Texas-based Occidental announced plans to build up to 135 DAC sites by the mid-2030s with plans to harvest the captured CO2 for industrial use or permanent sequestration.

DAC projects are planned beyond Occidental’s North American operations including third-party sites in the United Kingdom, Norway, and Canada.

Currently, DAC is expensive but with reproducibility, the cost per ton of CO2 should come down to make this technology viable for mitigating climate change.

$2 Billion Carbon Capture Project Announced By Strathcona Resources

Strathcona is an oil and gas producer located in Alberta. On July 10, 2024, Strathcona announced a partnership with the Canada Growth Fund (CGF) with $15-billion in assets, to develop CCS infrastructure for its steam-assisted gravity drainage oil sands facilities in Saskatchewan and Alberta. CGF and Strathcona will equally share initial capital costs.

Strathcona operations currently emit 3 million tons of CO2 annually. The project is expected to eliminate 2 million tons annually which still leaves a million tons entering the atmosphere annually.

It’s progress but why the two in partnership aren’t committed to removing all 3 million tons is beyond me. The CCS projects will be on site with the first to be located in Saskatchewan. This differs from the Pathways Alliance which envisions a network of pipelines to take captured CO2 and transport the gas to remote sequestration sites.

One issue of concern. No completion date for the first site was announced. Strathcona appears committed but we will know to what level by mid-2025 when the final investment decision is made.

Turning Carbon Dioxide Into Green Energy

Energy Dome, an Italian startup, is taking carbon dioxide (CO2) produced by clients, liquefying it on site and then using the gas to power a CO2 battery storage plant. The plant can be built on-site. A 200 Megawatt-hour (MWh) battery can be built in a flat space the size of 5 hectares (12 acres).

The stored CO2 is used to spin turbines to generate electricity which is then through a power purchase agreement dispatched back to the client. In May the European Investment Bank gave Energy Dome an award for its innovative, pioneering design which is already operating on the island of Sardinia since 2022.

To charge the battery, CO2 at near atmospheric temperature and pressure gets compressed. The heat generated by compression is stored and then used to provide energy to convert the gas to liquid. The liquid CO2 as it warms turns back into compressed gas which then powers a turbine to turn a generator and produce electricity. The battery is a closed and sealed system.

Each battery is built using off-the-shelf components. It can be rapidly deployed and the company recently announced it has an order book for projects in Italy, Germany, the Middle East and Africa. It recently opened a North American office in Boston.

Activated Charcoal Used to Capture CO2

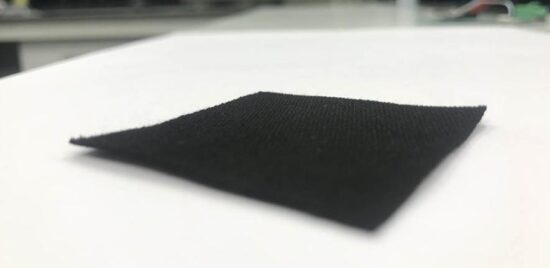

The above picture doesn’t look like much. It is cloth containing activated charcoal and hydroxide ions. Research being done at the University of Cambridge has shown that by energizing it turns into a direct air capture tool that removes CO2 from the atmosphere.

Using a battery-charging technique, the charged activated charcoal cloth becomes a sponge that soaks up the greenhouse gas. The results indicate that it may prove to be more efficient than current DAC technologies used by companies like Occidental’s Carbon Engineering and Swiss-based ClimeWorks. That could drive down the cost of per ton CO2 capture dramatically.

When I read the Cambridge press release I immediately thought back to when I had aquariums with water filters containing activated charcoal. So I wasn’t surprised in reading the material could potentially be used to clean the air of greenhouse gasses.

What I didn’t realize was that without charging the activated charcoal it wouldn’t bind with CO2. Adding hydroxide ions to the activated charcoal, however, is what makes that innocuous piece of technology seen above work. When charged it becomes a good CO2 filter.

States University of Cambridge’s Dr. Alexander Forse, who has led the research, “It’s a new way to make materials, using a battery-like process and the rates of CO2 capture are already comparable to incumbent materials. But what’s even more promising is this method could be far less energy-intensive, since we don’t require high temperatures to collect the CO2 and regenerate the charcoal sponge.”

Dr. Forse believes activated charcoal filters laced with different charged ions could be used in many future industrial applications. The Cambridge team recently submitted a patent application and their research results appeared on June 5, 2024, in the journal Nature.

Dr. Forse also notes in the Cambridge press release that reducing carbon emissions worldwide is the “most urgent thing we’ve got to do,” and their invented activated carbon filter represents only a partial solution to the global addiction of humanity to continue to burn fossil fuels which pollute the atmosphere and contribute to global warming.

[…] the atmosphere for 300 to 1,000 years states a NASA science report. Investments have been made in capturing CO2 from emission sources or directly from the air. So far, a few industrial emitters have added CO2 […]