Sequestering captured carbon is the fossil fuel industry’s answer to having its cake and eating it too. Harvesting the coal, oil, and gas stored by nature hundreds of millions of years ago is the raison d’etre of fossil fuel operations. The gigatons of carbon dioxide (CO2), methane (CH4), and other polluting gasses these operators produce directly and indirectly (when their products are burned by consumers) can now be remedied by capturing the polluting emissions along the way. This can be done by adding technology to existing extraction and production processes. Or it can be done after the emissions have entered the atmosphere through direct air capture. These technological solutions come with a steep price tag which with few exceptions, producers have been unwilling to pay without governments providing substantial financial support.

In Canada where the fossil fuel industry represents the largest carbon polluter, one project, Shell’s Quest, has been operating at an oil sands site since 2015 siphoning off CO2 and storing it in stable rock formations 2 kilometres beneath the surface. A second project, the Alberta Carbon Trunk Line, completed in 2020, is taking captured CO2 from industrial and fossil fuel production sites and transporting it 240 kilometres (149 miles) to be pumped into mature oil fields to enhance recovery. A third project is the Saskatchewan Boundary Dam, a coal-fired thermal power plant that has been in operation since 2014. Boundary Dam sequesters some of the CO2 it captures, but the rest is piped to an oil company operation to be used for enhanced recovery. So we have one project that is designed to reduce global carbon emissions, and two pretenders.

Then there is the Canadian federal government’s Natural Resources Ministry advocating for an investment tax credit for carbon capture projects that don’t specify where the CO2 gets stored. Applying it to enhanced oil recovery projects does nothing to help Canada meet our 40 to 45% emission reductions goals for 2030, or our net-zero 2050 goal.

Capturing CO2 directly from the air remains an expensive proposition. But an operating pilot project here in Canada is proving the technological viability of doing this. Carbon Engineering is the developer of a technology that initially priced CO2 capture at $600 per ton. Today that cost is approaching $100 US (approximately $130 CDN). Canada’s current federal benchmark price on carbon pollution is $50 CDN per ton. By 2027 it will hit $125 and in 2028 will be $140. So we are still five years away from achieving a viable direct air capture solution unless some other invention comes along.

Recent research done by a chemical engineering team at the University of Delaware has produced with one of those carbon-capturing inventions using hydroxide exchange membrane (HEM) fuel cells.

HEMs are not your average fuel cell and you won’t find any in vehicles today. Why? Because they are sensitive to CO2 in the atmosphere and quickly lose their performance capacity. This disadvantage for powering a vehicle is now being turned into a distinct advantage for capturing CO2.

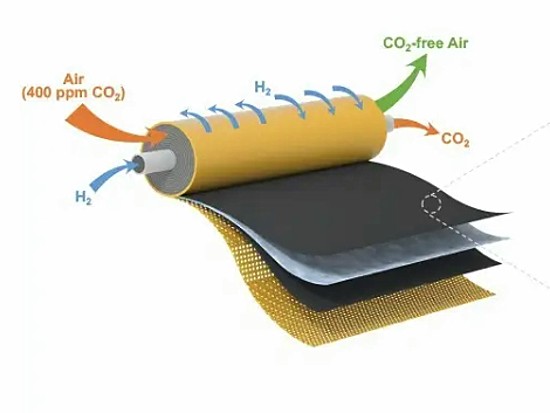

Yushan Yan is Chair of the Chemical and Biomolecular Engineering Department at the University heads up a research team that has tweaked HEM fuel cell design to turn it into a CO2 scrubber. The altered cell involves embedding an electrical wire within the separation membrane. The module is illustrated at the top of this article. It is designed as a compact spiral with multiple layers allowing for a large surface area in a very small volume. The electrically charged layer allows the HEM to continuously separate minute amounts of CO2 from the air as it passes through the cell. The patented design is simple and easy to replicate.

In testing, the research team used a 5-centimetre square (2-inch square) fuel cell which was exposed to airflows of 2 litres per minute and was able to capture almost 99% of the CO2. A suitable sized HEM fuel cell capable of powering an automobile would be about the size of a four-litre (one gallon) milk jug.

The research team believes there are many applications from removing CO2 in the cabins of spacecraft to CO2 scrubbers on submarines and airplanes.

An article appearing in Nature Energy, published on February 3, 2022, describes the research and technology in greater detail. And you can check out a media release produced for the University of Delaware’s website.