October 11, 2015 – A small Calgary, Alberta-based company, Carbon Engineering, with the backing of Bill Gates and oil sands magnate, Murray Edwards, has switched on a pilot project located in Squamish, British Columbia in the last few days, to chemically grab carbon dioxide (CO2) from the atmosphere.

Founded by David Keith, Professor of Public Policy and Applied Physics, Harvard University, with research from a wide range of scientists and engineers including work done at University of Calgary, this $9 million dollar pilot project will capture one ton of CO2 per day. According to CBC News that is equivalent to the output of 100 automobiles over a year.

How does it work?

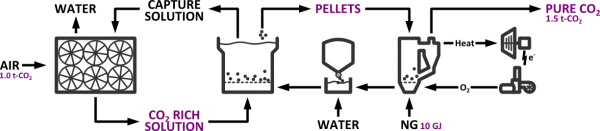

The illustration above explains the process. The air contactor, seen on the left brings normal atmospheric air into contact with a chemical solution that absorbs the CO2. The absorbed CO2 then is extracted from the chemical solution, the latter being reused. The extracted CO2 in liquid form then is cooked to release the gas which is then pressurized so that it is pipeline ready. CO2 gas extracted this way could ultimately be pumped into old oil fields to increase extraction, or simply could be piped into stable sandstone formations for permanent sequestration.

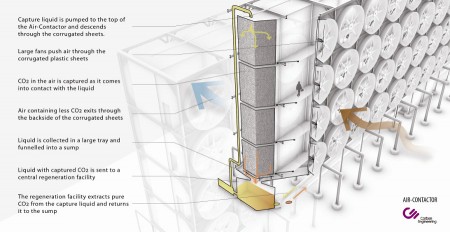

The key is viability is to maximize the amount of air being processed by the contactor. This is done using a large array of stacked fans (see image below) which allows the air to flow through making contact with corrugated plastic sheets containing potassium hydroxide solution that is constantly cycled through the system. The CO2 then binds with the potassium hydroxide which sinks to the bottom of the array where it gets collected and pumped to a regenerator. There the potassium hydroxide is extracted leaving solid calcium carbonate (CaCO3). The potassium hydroxide gets recycled to the array where it is pumped to the top to run down the corrugated plastic sheets once again where it can capture more CO2. As for the calcium carbonate left by the regenerator, it gets sent to a fluid-bed calciner which under high temperatures breaks down into calcium oxide releasing CO2 in gaseous form. The calciner uses natural gas as its fuel source. The heat generated is sufficient to provide the energy to power the entire array.

Other than the use of natural gas for heating, Carbon Engineering appears to have built a very efficient closed-cycle system. But is it commercially viable? According to its founders the price on carbon would have to be considerably more than it is today for the company to become profitable. The average weighted carbon tax being applied by governments today is around $10 U.S. per ton, far from the $100 that Carbon Engineering needs.

But many companies today are putting a price on carbon to prepare themselves for the day when carbon taxes will be applied globally. That could happen in the next couple of years after countries come to a global agreement at the upcoming Paris climate change conference.

Collecting CO2 from ambient air is far different from other carbon capture and sequestration systems (CCS) on the market today. Most of these focus on site emitters like coal-fired power plants and require additional investment in equipment to capture flue gases for CO2 extraction. They as CO2 collectors are far more efficient than what Carbon Engineering is attempting to do in capturing CO2 at 400 plus parts per million from the air surrounding us.

One promising byproduct of Carbon Engineering’s pilot project is the potential to use CO2 with added hydrogen to produce fuel. By 2017 the current plant could be producing 200 to 400 liters of gasoline or diesel per day. Consider the recent XPrize announcement and I would say that Carbon Engineering could be in the running to get some of that $20 million U.S. that is up for grabs.