In 2016, I described the GATEWAY Project which was to be located in Rotterdam, The Netherlands, a hub for connecting industrial greenhouse gas emitters to a common carbon sink under the floor of the North Sea. Almost eight years later, the name has changed to the Porthos Project, which aims to transport and store carbon dioxide (CO2) emissions from industrial sources near Rotterdam.

Porthos is not as ambitious as that which was first described in GATEWAY, but the completed project will be able to gather and store 2.5 Megatons of CO2 annually, last 15 years and top out at 37 Megatons sequestered beneath the seabed of the North Sea permanently. The compressor station and transport system infrastructure can be used and expanded over time to allow member European Union countries to use it for CO2 sequestration projects in the future.

The sequestration sites are empty or depleted natural gas fields three to four kilometres (1.9 to 2.5 miles) beneath the seabed. Construction began in April with plans to be operational by 2026. The name Porthos is an acronym which stands for The Port Of Rotterdam Transport Hub and Offshore Storage.

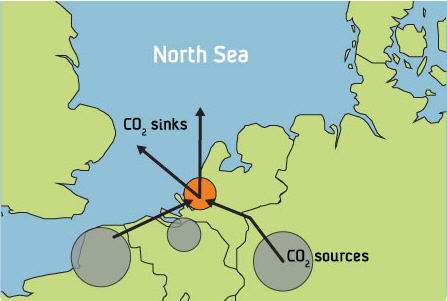

Why locate the hub in Rotterdam? The above map shows how central the port is to large industrial emitters. It is also a hub for North Sea oil and gas operations with a mature infrastructure and expertise to support pipelines to be filled with CO2 rather than oil or natural gas. Instead of onshoring those fossil fuels, the flow will be outbound with CO2 in the pipe going to an offshore North Sea platform before being pumped below the seabed.

Currently, 14% of The Netherlands’ total carbon emissions are produced by emitters within the immediate vicinity of Rotterdam. That’s why picking it as a carbon capture and sequestration (CCS) hub seems like the fastest way to reduce the country and surrounding region’s carbon footprint at a relatively low cost. The port hopes to reduce its carbon emissions by 10% annually once the project is completed.

What’s involved? The project requires new pipelines and a feeder network of smaller ones coming from industrial emission sources. The project’s infrastructure involves drilling under the seawall and building a network to cross several waterways, rail lines and roads in the port area. The CO2 will be transported from emission sources to the onshore compressor station and from there through a pipeline to a platform 20 kilometres (12 miles) off the Dutch coast. It will then be pumped underground.

The project is a partnership involving the Port of Rotterdam Authority, Gasunie, EBN, Royal Dutch Shell, Air Liquide, and ExxonMobil. Total cost is estimated to be €1.3 billion (almost US $1.4 billion).

The carbon storage site is a sandstone formation that used to be saturated with natural gas trapped under an impermeable layer of cap rock. When the field was being operated to extract natural gas, pressures within the sandstone layer declined over time. The CO2 injection will restore the original pressure within the sandstone, which will be monitored to ensure it never exceeds levels recorded when the natural gas extraction first started. Besides the construction of the onshore pipelines and compressor infrastructure, some upgrades are required for the offshore pipe to the platform and to the casing containing the pipe that will go below the seabed. The sequestration field will be deemed full once historical pressures are restored by the CO2 being injected into the site. At that point, the pipe will be sealed.