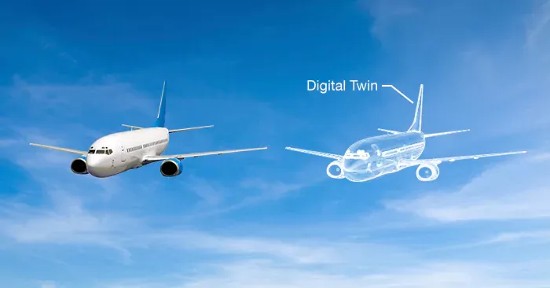

Digital Twins Are Not Simulators

Before delving into this topic it is important to differentiate between a digital twin and a simulation. A digital twin is a digital model of something real or intended to exist in the physical real world. A digital twin is indistinguishable from what exists in reality. A digital twin serves as a stable duplication of something real that can be tested. A digital twin can provide feedback to its real-world equivalent.

What a digital twin is not is a simulation. The latter is limited to the imagination of the designer. A change occurring in a digital twin, if tried on a real-world system or object, produces the same results. Simulations can have multiple results and follow many different paths.

I am more familiar with simulations and simulators. I remember years ago playing with Microsoft Flight Simulator. I could learn to fly and remember playing pilot. I was okay with takeoffs, but not so much with landings.

Then, a few years ago while on a road trip that took us through Ohio, my wife and I, along with our daughter and son-in-law, dropped in on the hometown of Neil Armstrong and the Armstong Air & Space Museum, in Wapakoneta. We had passed the museum when on previous road trips but this time decided to visit. That led to my second experience using a simulator. I tried to land the Lunar Excursion Module (LEM) on the Moon. My son-in-law mastered landing the LEM after a few tries. I crashed and crashed, and crashed. Thankfully, what I was playing with was not a digital twin with a feedback loop.

National Academy of Science Releases Digital Twin Study

The promise of digital twin technologies is increasingly being seen as critical to national policy in the United States and elsewhere. Why? Because it is seen as a means to accelerate scientific discovery and revolutionize health care, manufacturing, supply chain, and even our understanding of the interactions of the systems that govern our planet.

The American National Academy of Science (NAS) recently produced a pre-publication online edition of a consensus study and report on digital twins. The highlighted text provides you with a link.

One of its authors is Karen Willcox, Professor of Aerospace Engineering and Engineering Mechanics at the University of Texas-Austin. She describes the great promise that digital twins can bring to science and technology noting that there are serious research questions to tackle by using the mimicry, structure, context and behaviour of a physical system through a digital representation.

She notes that a digital twin can do what a simulation cannot. A digital twin can produce a bidirectional interaction between the virtual and physical through a feedback loop. This allows the digital twin to learn from its physical real-world counterpart and update itself. A digital twin can have predictive capability and inform decision-making for the use of the system or object to which it is twinned. These interactions could be fully automated, or feed recommendations to the system or object’s human operators to make adjustments as learned in the feedback.

The growing complexity of our world and the technologies we rely on are making digital twinning vital. Digital twins can help solve seemingly intractable problems and challenges. Introducing digital twins at the outset of projects from design to deployment can lead to “improved decision-making in biomedical settings, enhanced capabilities for making weather forecasts and simulating climate variability and change, and more efficient operations and production strategies,” states Willcox.

Four Types of Digital Twins

1. Component twins

This type of digital twin represents parts of a system or product. The automotive parts example comes to mind. A digital twin can be something as small as a screw or as big as an engine. Component twins can be used to model parts that during use may be subject to stresses or heat. Designers can see how well these parts perform and make improvements.

2. Asset twins

These twins are usually of an entire product rather than a component or part. They may be composed of component twins to test how an entire product operates in its digital version subject to real-world conditions. A nuclear power plant is a good digital twin-use example. A single wind turbine assembly undergoing digital performance tests is another.

3. System twins

This type of digital twin is exactly what it says, a digital model of an entire system looking at the performance of all the various components within it. System twins contain assets and components and look at how all of these relate and perform. A good example of use would be the operation of a power plant and supporting an electrical grid.

4. Process twins

These types of digital twins represent multiple systems working together. Whereas a system twin may look at the line of production in a factory, a process twin would model the entire facility including the human resources operating the machinery on the factory floor.

Use Cases for Digital Twins

Where would digital twins help us? A digital twin can be fit for purpose to meet something very small or something much larger. It can be used to analyze a wide range of data inputs, use advanced virtual models that have greater fidelity to their physical counterparts, and harvest and analyze vast amounts of computational information and data.

Here are a few examples:

- A digital twin can help doctors analyze a digital representation of cancer to design and test treatments.

- Another digital twin use in healthcare could create an online representation of an entire hospital to improve workflow, bed use, staffing and patient care.

- A digital twin of sensors and an aircraft could be used to optimize fuel efficiency, assess actual emissions, and provide reports on parts wear and tear to avoid future problems in the real world.

- A digital twin could test individual and sub-assembly parts for planned new automobile models before or even after the vehicles are built.

- A digital twin could emulate current supply chain processes and be a testbed for designed changes to determine what would be optimal in the real world.

- A digital twin of a nuclear power plant could spot before, during and after completion of the build to spot problems related to safety and operation and reduce production and maintenance costs.

- A “Whole Earth” digital twin could model the atmosphere, ocean, land and cryosphere, giving scientists new insights into the physical dynamics that govern extreme weather events and temperature changes, and help to design and support emergency preparedness and policy changes.

Concerns Developing and Using Digital Twins

There are considerations to keep in mind when developing or using digital twins. In building a digital twin the aggregated information could be deemed sensitive. Think about using digital twins in healthcare, for example, where patient privacy is a concern.

The NAS report identifies the security risk entailed in the large-scale deployment of digital twins for the defence industry and the manufacturing of key technologies. Think about the integrated workings of an aircraft or automobile as just one example where a digital twin with a feedback loop could be hacked leading to real-world disasters. Imagine, if the digital twin of an autonomous vehicle system were to communicate with its real-world equivalent after being compromised by a cybercrook.

The Market for Digital Twins is Expected to Explode

The major players developing digital twin technology include Microsoft Azure, IBM, Amazon Web Services, General Electric, Siemens, ANSYS, Dassault Systèmes, PTC, Robert Bosch and 15 other companies. In 2022, revenue from all 25 generated US $10.1 billion. By 2028, that number is expected to grow tenfold to more than $110 billion.