A technology developed at Stanford University could replace the industrial processes used by the cement, steel, and aluminum industries to produce their products. They have called the invention a metamaterial electrified thermochemical reactor. It uses high-frequency magnetic induction to generate the high temperatures these industries require to make cement, smelt iron to make steel, and bauxite to make aluminum.

An article that appeared last month in the open-access journal 50 Joule describes the engineering and science of the thermochemical reactor. Instead of burning fossil fuels to create heat, magnetic induction creates heat like an induction stovetop. Heating occurs internally within the reactor when electric currents interact with magnetic fields. The reactor heats an object all at once rather than heating from the outside in.

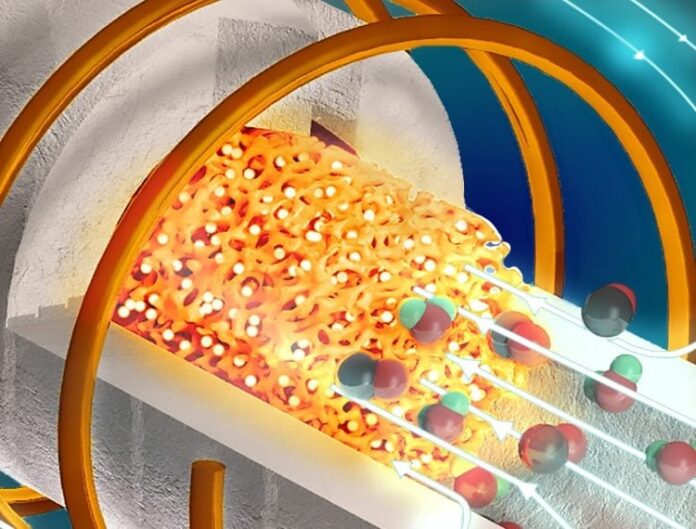

It may bear a resemblance to an induction stovetop but it is far more efficient. The electricity and reactor materials use high-frequency currents and three-dimensional ceramic lattices rather than the flat surface of a stovetop heating element. The lattice itself is made of a ceramic material that is a poor heat conductor. The honeycomb structure, however, allows catalysts to flow in that are far more responsive to the electric current causing efficient heat transfer.

The Stanford thermochemical reactor has other advantages over traditional production systems. Where steel foundries use enormous Bessemer Converters or electric-arc furnaces, the footprint of this device is far smaller. It doesn’t require external pipe feeds and conduits. It is easily insulated to have a high heat retention rate. It uses less energy to manufacture raw materials like iron, aluminum and cement. Its smaller footprint and simpler design are attractive features for operators of foundries and smelters. Finally, its low-carbon credentials make it a solution for the 21st century in our fight to reduce our global carbon footprint.

Jonathan Fan, who is an Associate Professor of Electrical Engineering at Stanford and the senior author of the paper describes the invention as scalable and an “ideal heating and heat-transfer” reactor solution. Powered by green energy, he notes “We’re pushing reactor performance to its physical limits.” The lattice design allows for an even distribution of heat in a three-dimensional space. Fan notes “You’re heating a large surface area structure that is right next to the catalyst, so the heat you’re generating gets to the catalyst very quickly to drive the chemical reactions.”

In the laboratory, the reactor is using a new Stanford-developed sustainable catalyst to create a reverse water gas shift reaction. In demonstrations, the reactor has achieved over 85% efficiency meaning it is converting almost all the electrical energy received into usable heat. Fan notes that “As we make these reactors even larger or operate them at even higher temperatures, they just get more efficient…That’s the story of electrification – we’re not just trying to replace what we have, we’re creating even better performance.”

The Stanford researchers are working with cement manufacturers as well as partners in the oil and gas industry to adapt the technology for them. They have also demonstrated its use for turning captured carbon dioxide (CO2) into a sustainable fuel.

Fan states, “Electrification affords us the opportunity to reinvent infrastructure, breaking through existing bottlenecks and shrinking and simplifying these types of reactors, in addition to decarbonizing them.”