Generation of electricity represents one-third of the energy equation. The second component is transmission. The third is storage. Renewable sources such as wind, solar, wave and hydroelectric power generation can fluctuate. The wind may not always blow. Waves can turn to calm. Clouds can decrease energy from the sun. Even hydroelectric power can be impacted by winter melts, snow packs and precipitation. The electric power grid needs balance to deliver energy as industry and consumers plug in. With the energy generation peaks and lows of renewable sources storage technology becomes one way for the grid to manage the variability of power generators.

The investment in these renewable sources is leading to a parallel investment in energy storage technologies. It is estimated that between 2011 and 2021 total worldwide investment in energy storage is expected to exceed $122 billion. What do these technologies look like and where is innovation taking us?

Pumped Storage Technologies

Hydroelectric power generation has always been a very inexpensive way to generate energy. A cubic meter of water falling 100 meters generates .272 kilowatts of power. What is to stop hydroelectric power stations from using untapped energy generated during evening hours to create new generation capacity by pumping water uphill into a reservoir for use when peak power demands require it.

Pumped storage installations first appeared in the 1890s in the European Alps. The principle behind pumped storage is simple. Water is pumped from a location at a low elevation to a location with a much higher elevation. This is done at times when there is a surplus of electricity. When there is significant electricity demand the water flows back downhill. Optimally pumped storage facilities require a height differential between the source and elevated storage of at least 100 meters. This limits where pumped storage installations can go. Currently there are 81 pumped-storage hydroeclectric facilities around the globe. More are coming on line as wind power as well as other power generation sources are used to create this cheapest way to store energy. Worldwide capacity today for this type of storage is estimated to be 90 gigawatts. (See Science Illustraded, July-August, 2011, “10 Methods to Store Clean Energy.”)

Compressed Storage Technology

There are two types of compressed storage technology. The first is micro-based and commonly available in cars that run on natural gas today and compressed hydrogen for use in fuel cells. (Check out Iceland’s hydrogen fuel cell buses in this video.) The second is large-scale compressed storage known as compressed air energy storage or CAES.

In the case of the first the most promising future technology is the use of hydrogen for transportation. We’ll look at transportation technology in a future blog. For now this discussion will focus on CAES which is still in its infancy.

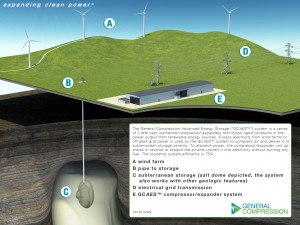

By infancy we are talking about 140 years because deriving energy from compressed-air to generate electricity goes back to the 1870s. But the first commercial plant using CAES only opened in Germany in 1978. A second facility was commissioned in 1991 in the United States and several more are under development. The experience of that second plant is worth retelling. A salt dome in Alabama became the storage site for compressed air. A geological pocket, just under 300 meters long (900 feet) and 75 meters wide (238 feet) was formed by pumping water into the salt formation until all the salt dissolved. When the water was pumped out the remaining salt sealed the man-made cavern forming an underground air-tight container. At the conventional coal-fired power plant, during off-peak demand periods, the electricity generated runs a compressor to pump air into the cavern. This process is called charging. When peak demand requires more energy than the conventional plant can deliver air is released from the cavern to drive a turbine. The system has been working continuously for two decades.

CAES can use depleted aquifers, abandoned mines, porous rock such as sandstone, and underground caverns for storage. As long as the underground environment can absorb the gas under high pressure without destabilizing the environment around it, it becomes a very inexpensive storage medium. Compressed air gets warmer. The combination of higher pressure and heat provides two sources of energy when the air is released.

CAES can be combined with renewable energy resources such as wind balancing the delivery of electricity across the grid. Latent energy can be stored when the wind is blowing but power demands are low such as evenings and weekends. In a scientific paper published in 2007, “Controllable and affordable utility-scale electricity from intermittent

wind resources and compressed air energy storage (CAES)”, the author, Alfred Cavallo, states “Intermittent wind power can be transformed to a controllable power source with hybrid wind/compressed air energy storage (CAES) systems. The cost of electricity from such hybrid systems (including transmission) is affordable, and comparable to what users in some

modern industrial economies already pay for electricity.”

In the United States since 2007 a number of new CAES projects have received initial funding. These include plants in Ohio, California, New York and Iowa. Some of these plants are storing the compressed air in abandoned limestone mines, porous sandstone, salt caverns and depleted aquifers.

Large Scale Battery Technology

When we think of batteries conventionally we think on a small scale. Batteries of this type that run your watch, a flashlight, or digital camera and cellphone are not the technology that is being developed for utilities. Today’s lithium batteries stacks may be able to run an electric car (although new lithium storage technology is proving to be scalable) but for truly significant power that can supplement the lows of renewable energy wources we are talking about much larger capacity battery storage systems.

Vanadium redox batteries fit that bill. These are chemical-solution based systems that can be scaled to enormous size. First pioneered by NASA in the 1970s vanadium redox technology has almost unlimited capacity simply by increasing the battery size. A vanadium battery requires large volumes of vanadium in solution circulating through storage tanks. Vanadium has the ability to exist in four different oxidation states, a very useful property for battery technology. Second generation vanadium/polyhalide batteries produce almost double the energy density of the first generation technology. They also can operate in a wider temperature range making them highly suitable for load balancing in association with wind, solar and other variable renewable power sources.

Sodium-ion batteries represent another scalable technology that shows promise. These batteries combine a water-based electrolyte with sodium to create a non-toxic power source. Developed at Carnegie-Mellon University in Pittsburgh, sodium-ion technology is expected to be in production by 2013.

Liquid metal batteries combine liquid metal alloys and molten salt as the electrolyte to generate 1o times the energy of present-day high-end batteries. The different densities of the liquids keep them separated inside the battery. To keep the metals liquid the batteries have to be heated. Research funded by Bill Gates and ARPA is ongoing to see how the battery can be scaled in such a way to minimize the reliance on external heating sources.

Zinc redox batteries use a solution of Zinc bromide or Zinc cerium to generate energy. When energy is needed, the electrolyte solution is pumped into an electrochemical cell to convert chemical energy into electricity. When the electrolyte is discharged, it is pumped back while a current is applied to it to recharge it. Zinc redox batteries are being used in a wind farm project in Minnesota.

A nanophosphate lithium-ion energy storage system has recently been sold to Dongfang Electric Corporation in China. This is a scaled up version of the lithium-ion technology that is commonly used with laptop computers. The system in China will be incorporated into a wind farm project.

A Quick Note About Small-Scale Battery Storage

Today lithium-ion and nickel-cadmium rechargeable technology is state of the art for small appliance battery storage. But not for long. If you remember the flux capacitor in the movie, “Back to the Future,” you’ll love what scientists at MIT are contemplating as our storage future for small devices. It is of all things – the capacitor but not a flux capacitor. This is capacitors with nanotube technology that cover the electrodes increasing the amount of charge that can be stored.

Thermal Technologies

In Part Four of this energy blog we talked about the use of geothermal energy. But in this section we focus on capturing solar energy in a heat sink using phase change materials such as molten salt.

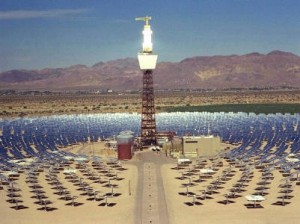

What is a phase change material or PCM? It is a material that through heating and cooling, going from liquid to solid to gas and back, can release a significant amount of energy. For the purpose of power generation and storage limitation only solid-to-liquid and back to solid is useful. In a 2009 article appearing in Scientific American, David Biello described a solar-thermal power plant in Southern Spain that used parabolic mirrors to heat up a sodium and potassium nitrate mixture enough to turn it into a liquid. Ordinary table salt melts at 800 degrees Celsius. The plant uses the heat released from the PCM to boil water and turn it into steam to drive turbines connected to power generators. At the time of writing the power plant had the capacity at at that time to pump out electricity from it s molten salt reservoir for eight hours after sunset.

What other PCMs are presently being used for power generation? In addition to salts, sugar alcohol, some organic materials and metals like zinc and tin are being evaluated as potential thermal storage media.

The latest new breakthrough in large-scale storage technology extends the capacity of lithium-ion batteries, currently (forgive the pun) a primary energy storage medium.

By combining sulfur-coated hollow carbon nanofibers and an electrolyte additive, researchers at Stanford University have designed a battery that overcomes the limitations on lithium-ion batteries for use in electric cars and larger storage requirements such as the grid. The problem has always been that the energy density of these batteries is low when compared to their volume and weight. By coating the inner hollow of carbon nanofibers with sulfur and an electrolyte additive, the Stanford research team has been able to quadruple battery storage capacity.

Lithium-sulfur batteries have been tried before but the technology was prone to rapid failure from recharging. In creating a unique fabrication process in which the sulfur coats the inside of hollow carbon nanofibers, the sulfur is not directly exposed to the electrolyte solution and therefore does not dissolve into it rapidly reducing the battery’s capacity.

[…] The rebirth of the electric motor in automobiles represents a move away from fossil-fuels and a serious reduction in carbon emissions. These vehicles combine electric-motor drive systems with batteries and sustain a charge for 100 or more kilometers (about 60 miles). These are urban commute vehicles at best, limited by current battery technology. The electricity sustaining this technology comes from plugging-in to a power source which may be a coal, natural gas or other fossil-fuel power plant, and therefore not exactly a zero-carbon solution. But it represents a significant initiative with engineers and scientists devoting considerable effort to finding greater efficiency and capacity in storage technology while reducing it scale (see my blog on energy and storage). […]

The World Bank Group is contributing close to $300 million of a $1.4 billion investment in a Morocco-based concentrasted solar project. The European Union and countries around the Mediterranean basin see the Sahara Desert as an ideal location for the development of solar-powered infrastructure. See the link for more information: http://moroccotomorrow.org/2011/11/20/world-bank-group-co-finances-morocco%C2%B9s-ouarzazate-500-mw-solar-thermal-power-project/