For solar, wind and wave energy there is always a period of time when these technologies go down. When the Sun sets a solar array can no longer convert photons from sunlight into electricity. When the wind dies wind turbines no longer operate. When there are no waves or tidal action is minimal wave technologies cannot generate power. That’s where storage technology enters the picture, filling in the gaps. So any advances in batteries and energy storage can only mean we are getting closer to making renewable energy generation a true alternative to fossil fuel and nuclear power.

The term battery covers a wide range of technologies. A battery can be the flat lithium cell running your wristwatch (for those who still wear one) or your mobile phone. A battery can be the “A” battery in your flashlight, “AA” in your electric toothbrush, “AAA” in a penlight, or the battery in your tablet, notebook, gasoline-powered, hybrid or electric car, or a compressed air storage, chemical or molten salt technology found in continuous solar power stations.

The commonalities for all these “batteries” is – we need to make them more efficient, we need to extend their power capability, we need them to last far longer, and we need them to be less chemically toxic.

Three recent battery technology announcements caught my eye:

1. Boulder Ionics, a company in Colorado, is developing ionic liquids, salts that are molten below 100 degrees Celsius (212 Fahrenheit), for use as electrolytes. Ionic liquids could replace conventional electrolytes shrinking battery form factors and doubling capacity. Instead of the concrete block sized battery in your gasoline-powered car, you would have a battery about the size of a flashlight.

Using ionic liquids could improve lithium-ion storage capacity by a factor of 10. So that battery in your laptop could run continuously for days rather than hours.

In addition to the efficiency gain that Boulder Ionics’ technology brings, it has also improved on the manufacture of ionic liquids making them in greater quantity and cheaper than conventional electrolytes. The industry at large has always known about the potential of ionic liquids but shied away from them because to manufacture them took days to get sufficient production volume. But Boulder Ionics has developed a continuous rather than batch process making ionic liquid electrolyte in six minutes rather than three days. Instead of requiring a large chemical plant to make ionic liquid for 100,000 electric cars, Boulder Ionic can do this in a space no larger than a living room in an average home.

Ionic liquids do not evaporate and can be exposed to the air, which brings us to the second technology announcement.

2. Metal-air batteries rely on the oxidation of metal when exposed to oxygen in the air to generate energy. Fluidic Energy, an Arizona-based start up, is using ionic liquids in a metal-air battery that will produce 11 times the energy density of current lithium-ion technology and at one-third the cost. The company recently received a $5.13 million research grant to help it get this technology up and running.

Traditional metal-air batteries use water-based electrolytes that can evaporate when exposed to air. This causes the batteries to fail. In addition water is far less electrochemically efficient, and when subject to excessive cold or heat can freeze solid or boil away. But with ionic liquids all those deficiencies go away. Ionic liquids survive as a liquid in sub-zero and above the water boiling point temperatures.

Metal-air batteries using ionic liquids become practical replacements for current lithium batteries when there is sufficient volume of the stuff available for production. Boulder Ionics is now making that possible. What it will mean is energy storage in electric cars that will, on a single charge, allow you to travel 700 to 800 kilometers (400 to 500 miles). And it will mean that the battery you will use to achieve this will be no bigger than your gas-powered car’s lead-acid battery.

3. Our last technology announcement concerns solid oxide fuel cells (SOFC). These are fuel cells that contain electrolyte sandwiched by two porous electrodes. Pacific Northwest National Laboratory in the state of Washington is building SOFC technology to power individual homes and neighbourhoods. These fuel cells achieve up to 57% efficiency, significantly higher than industry standards between 30 and 50%.

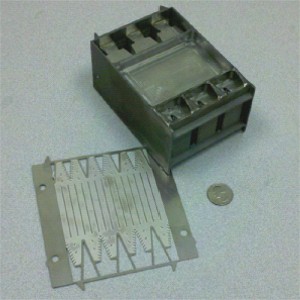

The goal is to create distributed power sources rather than large centralized power plants while addressing reduced carbon emissions. The SOFC technology that Pacific Northwest has developed includes micro-channel technology, tiny looping channels each narrower than a paper clip that are etched into a heat exchanger. The heat exchanger allows the fuel cell to recycle heat generated by the interaction of the two gases within the fuel cell in a closed loop system making it far more efficient. The development team expects to achieve 60% efficiency with a few more adjustments and then develop capacity to decrease SOFC costs.