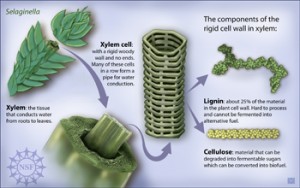

One of the challenges of producing cellulosic ethanol comes from trying to break down the biomass into the sugars and starches that ultimately can be converted into fuel. The problem is lignin, the component in plants that gives them structural strength. That’s why most of the ethanol produced today comes not from stems and stalks of cane and corn but from the harvested and partially processed yields.

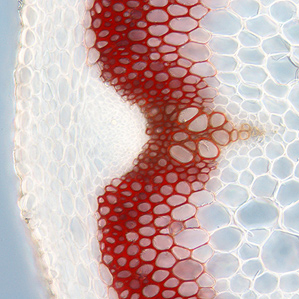

Lignin occurs in two types of plant cells – fiber and vessels. The fiber cells provide structure. The vessel cells provide the conduits that channel fluids through the plant. Together they make up as much as 25% of plant biomass. Researchers are experimenting with genetic modifications to these cells eliminating a key gene responsible for lignin. The problem, however, is any modification affects the structural integrity of the plant as well as the water transport system which allows the plant to receive nutrients and grow.

So which cells would researchers want to genetically modify? Certainly not the vessel cells because that would negatively affect growth and viability. But the fiber cells could be modified selectively in some areas of the plant where structural integrity would not matter.

Why do this? Because producing cellulosic ethanol today is not cheap. Companies in the field have found pretreatment, that is cooking the biomass in a hot acid bath to break down lignin to cellulose to sugar, to be very expensive. The process which is called pulping involves too many chemical additives and too many steps.

In a previous blog I wrote about switch grass as a viable biofuel source. It contains lots of lignin. Researchers at Lawrence Berkeley National Laboratory have shown that they can selectively target the plants’ lignin content in specific areas without affecting the overall structural integrity of the stems, stalks and vessel cells. If this can be made to work then switch grass and poplar may replace corn as principle biofuel crops.

Currently corn ethanol costs 55 cents a liter or $2.50 U.S. a gallon to produce. With genetic modifications cellulosic ethanol production could reduce the production cost of a liter of ethanol from biomass by 26 cents or a $1 per gallon U.S. That may not seem like a lot but right now every liter of gas sold in Canada and every gallon in the U.S. contains today ethanol costs are heavily subsidized in the United States and other countries by tax incentives to encourage production.