In 2011 Canada exported on average over 2.3 million barrels of oil every day to the United States. 1.6 million of those barrels came from bitumen deposits in Northern Alberta. Some came from similar deposits in Northern Saskatchewan.

Bitumen has other names: oil sands, and less flattering, tar sand. The latter two are seen as pejorative terms for what has been an important resource for economic development in Western Canada. Bitumen is a flash point for controversy in Canada pitting Eastern Canadian provinces against those in the West, being cited for an overly inflated valuation of the Canadian dollar, now described by many to be a Petrodollar, another pejorative.

I have written about bitumen in this blog before but for those of you who are coming by for the first time here’s a quick review. Bitumen is oil bound in sandy deposits. It has been mined a variety of ways over the last 60 years. Where oil sands have been near the surface they have been dug up and carted off to processing facilities where the oil gets separated from the sand and the waste water with solvents gets flushed into large settling ponds. One of those ponds attracted migrating ducks a few years ago and when they landed on the surface they soon died.

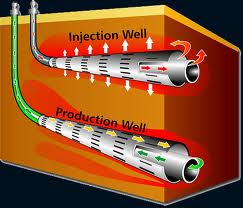

Deeper bitumen deposits are pumped out of the ground after high-pressure steam with chemical additives is injected into them to make them viscous. This method also uses a lot of local water which when extracted along with the oil contains lots of contaminants.

Bitumen detractors argue that the methods for creating oil from bitumen use such a significant amount of energy that the final product, synthetic crude, provides little net benefit.

And to make matters worse, both methods of mining bitumen contribute to atmospheric greenhouse gases. The Pembina Institute, a Canadian non-profit think tank, reports that if we were to extract all of the proven bitumen reserves considered economically viable at between $90 and $100 per barrel, the carbon emissions generated would equal 64 tons of greenhouse gas per person in Canada and the United States. That would be equal to 75% of our carbon budget for the next five centuries.

If We Can’t Kick the Oil Habit We Have to Make the Industry Less Polluting

Modern industrial societies have yet to find an energy alternative as reliable as fossil fuels. Hence the search for clean coal technology and less polluting ways to extract and process bitumen. The oil companies and governments are not burying their heads in the proverbial sand, in this case oil sands. Instead government and industry are collaborating to find better technology that lowers the carbon footprint as we make the transition from fossil fuels to reliable renewable energy sources.

A new bitumen extraction technology is being tested by a consortium of companies with funding assistance from the Alberta government. The goal is to reduce the carbon footprint and water requirements in bitumen production. The project is called ESEIEH, meaning Enhanced Solvent Extraction Incorporating Electromagnetic Heating. Four companies, Harris Corporation from Melbourne, Florida, Laricina Energy Ltd. and Nexen Inc., both of Calgary, Alberta, and Suncor Energy Inc., Canada’s premier developer of bitumen extraction technology, have successfully tested an injection technology that replaces steam with electromagnetic heating to extract bitumen from underground (see the diagram below).

Bitumen extracted using ESEIEH provides a number of benefits including:

- Reduced greenhouse gas emissions

- Elimination of water in the extraction process

- Improvements in the quality of extracted oil with the elimination of steam from the process

- Increasing the bitumen deposit reserve capacity by making formerly uneconomical deposits financially attractive

The electromagnetic heating technology has been pioneered by Harris Corporation and originally tested in 2011 in Florida. The proof-of-concept test in 2012 was conducted in Northern Alberta in field conditions. An expanded test is scheduled for 2013 before ESEIEH becomes commercially available.

Would you happen to have any update regarding the advancement of this ESEIEH system. When might the additional testing begin/completed?

Thanks Roman

With CNOOC’s acquisition of NEXEN I would guess that the cost for implementing ESEIEH will be covered and we should see it go ahead shortly.