May 4, 2017 – Why would you want to 3D print with an erasable ink? Researchers at Karlsruhe Institute of Technology, Germany, have developed a photo resistant, chemical-reactive material, as ink. When printed it can be altered or erased by heating it to 50 Celsius (122 Fahrenheit) degrees. When combined with other 3D-ink materials the erasable ink opens up a new world of possibilities when constructing objects for use in a wide range of applications.

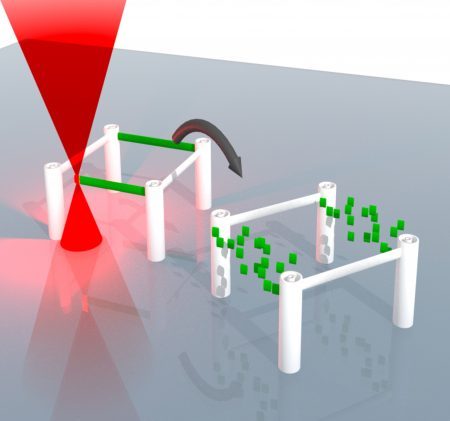

“The ink with defined breaking points can be used for a variety of applications,” states Markus Zieger, one of the authors of the paper that describes the print material uses. Printing with two different materials, one erasable, allows designers to create 3D-printed structures incorporating temporary supporting frameworks. Once printing is complete, erasable parts disappear leaving finished 3D-printed material in place. Zieger talks about other applications including 3D designer petri dishes for use in biological experiments, and erasable electroconductive wiring structures. I can think of a few others where this invention will prove to be groundbreaking.

I can think of a few others where this invention will prove to be groundbreaking. For example, medical applications go well beyond petri dishes. Imagine using the technology in regenerative medicine combining a stem cell ink with an erasable to create temporary scaffoldings with cells precisely positioned in a knee. hip, or shoulder joint where they can be stimulated using a growth medium to generate cartilage. Or using erasable ink to create light-weight construction and manufacturing materials containing microscopic pores left after the erasable ink disappears. The end result would yield lighter structural components that retain the tensile strength of objects weighing twice as much. These new materials could prove revolutionary for airframes, rockets, cars, buildings and more. Erasable ink could be used in production processes where current electron-beam lithography is used in the field of semi-conductors.

The Karlsruhe-developed ink is made up of phenacyl sulfide, a chemical that is photo-resistant and capable of being laser-etched on to surfaces to create microstructures that can then be degraded on demand. The paper describing the ink and its potential is to published on May 8th, 2017 in the Angewandte Chemie, a publication of the GDCh, a 31,000 member community of German researchers working in the field of chemistry.