The Province of Alberta in Canada is the main site of the country’s largest petroleum reserves. These are oil-saturated sands and one of the world’s largest reserves of fossil fuels. This perceived bountiful resource could become Alberta’s worst nightmare if the relentless increase in global atmospheric temperatures continues. With yesterday’s release of the IPCC’s Sixth Climate Assessment, a document we will review in depth in future postings, it appears there will come a point in time, and likely much sooner than many in the oil industry suspect, when the world will foreswear Alberta’s largess for the purpose of self-preservation.

Wherefore will go Alberta in circumstances where their oil sands will no longer be a source of fossil fuels to be burned for energy and transportation? For what can oil sands output be used when the world weans itself off its current dependence on petroleum and natural gas?

In a small way, Alberta has tried to envision a future without the oil sands being used for oil production, but rather for something else. That’s why they launched the Carbon Fibre Grand Challenge (CFGC). With $26 million in prizes, the goal is to stimulate competition to develop carbon fibre production using oil-sands feedstock. Alberta wants to produce high-value products from its oil sands rather than synthetic crude that gets burned and pollutes the atmosphere.

The province, however, is seeking a solution to its future relevance taking baby steps of which CFGC is one. Having said this, it still is an important initiative that could have enormous Canada-wide impacts.

What is carbon fibre?

Carbon fibre is less than a tenth the thickness of human hair. It contains carbon atoms almost exclusively. It is lightweight yet strong and can be bundled with other carbon fibres, woven, pressed and moulded. Carbon fibre material can be turned into tubes for bicycles, tennis rackets, and golf clubs. As a sheet, it can be moulded and turned into body parts for automobiles and trucks. Today, it is in the wings of modern aircraft replacing aluminum and steel. It is in Rocket Lab’s Electron rocket. And in construction, it can be used instead of concrete, brick, wood, and even steel.

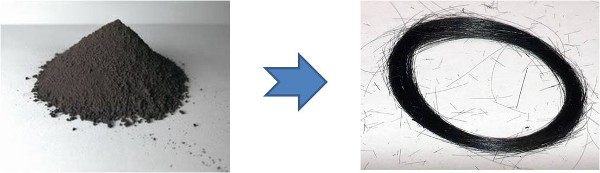

How is most of it manufactured today? It is largely produced using liquefied natural gas as the material source. But a byproduct material from oil sands called asphaltene may be a much better feedstock for carbon fibre production.

What is asphaltene? When you read the definition of this material you wonder how anyone would ever have considered it a useful product. By definition, asphaltene is the dissolved remaining solids coming from crude oil production. It along with paraffin, naphthene, aromatics and resins are substances removed during the refining of oil. If you think asphaltene sounds a lot like asphalt, you are absolutely right. Asphalt is made from asphaltene for use on roads and roofs.

The biggest carbon fibre challenge is cost

The production process for this material starts with natural gas used to create an acrylic resin, the precursor product to finished carbon fibre. It is a two-step method making the per kilogram cost prohibitive when compared to products it could potentially replace. As a result, carbon fibre today is found in a limited number of high-end, low-volume products. It is used by the military for field gear including helmets. It is found in high-end electronics like smartphones to keep them light and durable. It is used in medical imaging equipment replacing the heavy components in a radiology suite. And in automobiles, it gets used in seat frames, instrument housings, and for bodywork on very high-end pricey vehicles.

But what if carbon fibre were to replace steel, aluminum, plastic, concrete, wood, and brick? If it could be priced right, which means the manufacturing costs could be dramatically reduced, it would provide a material alternative with enormous benefits.

Let’s just look at steel used in the automobile industry. Today, the industry consumes 234 million tons of steel annually. Replace it with carbon fibre and you do at least two things:

- you remove a significant amount of greenhouse gas emissions that the steel industry produces.

- the end products produced are stronger and lighter, and in the case of electric vehicles (EVs) capable of a much greater range because of the reduced weight.

Carbon fibre from Alberta’s asphaltene could provide enough raw material to fill the needs of Canada’s automotive industry let alone be a valuable export product to the United States and Mexico where vehicle manufacturing and part suppliers are found.

Making the Oil Sands Relevant in a Net-Zero World

The Alberta government’s small CFGC investment to reduce the cost of manufacturing carbon fibre by at least 50% from current production processes is a baby step, but nonetheless, an important one to achieve a long-term future for an oil sands industry that will be dramatically impacted because of the necessary enforcement of climate change policies.

Reducing the cost of carbon fibre by 50% and ramping up production capacity could begin to make the material more competitive with high-end steel products. Getting the cost to be 80% less would make carbon fibre a game-changer.

The Competition

CFGC is a three-phased competition that first launched in 2021. Phase 1 has already been completed and Phase 2 will conclude in July of this year. It is Phase 3 which opens on May 1, 2023, where the meat and potatoes of CFGC will be realized.

Applicants to Phase 3 do not have to have entered either of the two previous phases. The objectives include:

- An ability to demonstrate manufacturing of carbon fibre from Alberta oil sands feeds.

- An ability to produce prototype end-use products.

- A demonstration of positive environmental outcomes from the manufacturing process.

- The manufacture of more than 1 kilogram (2.2 pounds) of carbon fibre weekly during the competition with the end product demonstrating the tensile strength to meet commercial needs and end product user performance requirements.

- The cost of manufacture at less than $9 USD per kilogram, or 50% less than any incumbent competitors.

- The ability to scale manufacturing to 2,000 metric tons or more per year.

- The capacity to consume 10,000 metric tons or more of the precursor product derived from oil sands per year by 2030.

- A demonstration of built prototype end products using carbon fibre.

- Incorporation of circular economic principles to cover material reuse and end-of-life strategies.

- An estimate of greenhouse gas emissions produced and other socio/environmental impacts of the processes developed.

The Phase 3 deadline to apply is June 15, 2023. Applicants can register for the CFGC webinar taking place later this week to get more information. Funding notification will be given in July of this year with between $200,000 and $4 million CDN awarded for successful applicants. The earlier project start date would be September 1, 2023, with a completion date on August 31, 2026.