August 5, 2015 – Graphene is seen as a material that is altering our technical world. But it isn’t alone. In the past few weeks two others have joined the new materials world of electronics. One is gallium nitride (GaN), and the other is sol-gel.

The Gallium Nitride Energy Revolution is About to Happen

Cambridge Electronics, Inc. (CEI), whose motto is “Dream it. We’ll power it,” is a Massachusetts company on a mission to reduce energy consumption while giving energy users access to all the familiar technology they want and need.

How can it achieve this promise?

Through a new semiconductor material, gallium nitride (GaN).

Already being used in LED light bulbs, television and computer displays, and mobile phones, GaN has efficient light emission capability, something silicon cannot duplicate. But silicon remains the defacto material of choice semidconductors and transistors found in all the computing devices of our modern world.

CEI, through GaN, hopes to change because not only is the material more efficient in light emission, it also handles power more efficiently than any silicon-based transistor.

Over nine years CEI has been perfecting GaN and today it can outperform silicon providing 1/10th the resistance of silicon transistors. This means faster switches, faster computers, and smaller form factors. For example a GaN power adapter can be integrated into a laptop and other electronic devices eliminating the clunky brick that is commonly comes with a device’s power cord.

It also means huge savings for energy utilities who will benefit not only from the use of GaN in power generating equipment but also in capacity to fulfill consumer demand.

So why aren’t we seeing a flood of electronic devices on the market made from GaN now? Because the expense of GaN manufacturing when compared to silicon has always been its Achilles Heel. But that’s changed. New GaN manufacturing techniques that mimic silicon wafer fabrication have brought the cost down to match the latter.

It should be a no brainer for GaN going forward, a material that cuts power consumption by more than 90%, produces the same or better levels of performance, and reduces the size and cost of electronic devices. Massachusetts Institute of Technology, the brain trust from which CEI was hatched believes using GaN in data servers, electric vehicle inverters, solar power inverters, industrial motor controllers, and other electronics will produce $900 billion in energy savings annually by 2025. That’s impressive.

But don’t count silicon out just yet. That’s our next story.

Hybrid Silica Changing Sol-Gel Supercapacitors

A new material made from a common fatty acid, octylphosphonic acid, may soon be found in supercapacitors used in electromagnetic propulsion, electric vehicles, defibrillators and other instant quick-discharge devices. Sporting higher energy density than lithium-ion we may even see batteries made with this material.

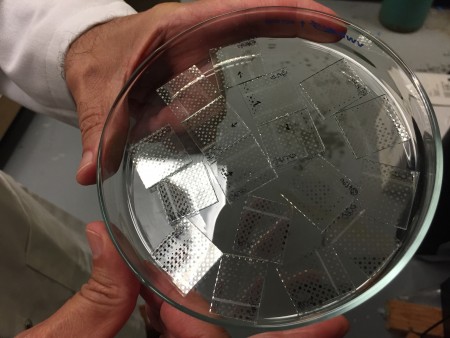

Called sol-gel thin film, it is made up of a single layer of silicon atoms and a nanoscale self-assembled layer of octylphosphonic acid. The structure provides low current leakage, high energy extraction and heat tolerance.

Performance of sol-gel thin film electrodes at Georgia Tech’s laboratories has exceeded all existing commercial electrolytic capacitors and thin-film lithium-ion batteries. States Professor Joseph Perry, School of Chemistry and Biochemistry at Georgia Tech, “sol-gels…such as phosphonic acids are well known…but to the best of our knowledge, this is the fist time these two types of materials have been combined into high-density energy storage devices….this is the first time I’ve seen a capacitor beat a battery on energy density.”

The research into sol-gel supercapacitors appeared in the July 14th edition of the journal, Advanced Energy Materials. Now the question becomes, can the materials be scaled up and become cost competitive.