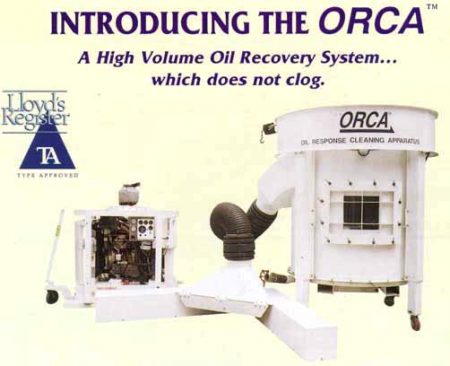

June 23, 2017 – ORCA stands for Oil Response Cleaning Apparatus. It is described as a virtually clog-proof marine clean-up machine by its inventor, Riz Khan. Khan developed it after the Exxon Valdez oil spill off the Alaska coast. That spill amounted to 257,000 barrels or 35,000 metric tons, roughly equivalent to 17 Olympic-sized swimming pools of oil. For engineers in the oil spill clean-up business, I can understand Khan’s motivation.

Since development, the Singapore Oil Spill Response Centre had employed Orca to deal with a tanker spill that occurred in 1997. According to Chris Richards who was the service manager for the Singapore Centre, when compared to other oil containment and collection systems, only ORCA worked continuously without clogging.

The ORCA weighs about 590 kilograms (1,300 pounds). It uses a very large suction hose connected to an 116 horsepower hydraulic power pack capable of lifting a 28-kilogram (60-pound) bag of sludge 30 meters (approximately 100 feet) vertically in four seconds. ORCA can retrieve from 500 to 1,500 barrels per hour depending on the viscosity of the oil and weather conditions.

Danny McKeowen, a former Special Adviser to the Saudi Government, has described ORCA as the best technology available for oil spill recovery. He is convinced it is “virtually impossible to clog” and suitable for desludging tankers, and picking up tar balls and debris from beaches, harbours, lakes, rivers, and shipyards. ORCA can be mounted on trucks for inshore use and flown to oil spill sites by helicopter where it can be deployed on a cleanup service ship in less than 20 minutes.

But what makes ORCA unique in the oil spill response technology world is its non-oil spill uses. Khan sees ORCA as a solution for cleaning up the 5 to 13 million tons of plastic that flows into the world’s oceans annually. Watch the video to see ORCA’s capabilities.

Khan has the right background. He spent more than 40 years in the shipping industry and today operates his own maritime investment consultancy called Tavlon Commercial Enterprise. He wants to deploy ORCAs globally and is seeking investment partners to bring down the cost of manufacturing.

ORCA has been tested by the American Bureau of Shipping and has received “Lloyd’s Register Type Approval” certification indicating it conforms to recognized industry quality standards.

My only question for Khan is this: Once his ORCAs have collected all this plastic what will we do with it? If we bury it in a landfill, it presents a future pollution problem. If we can find industrial uses for it, however, that permanently sequesters the recovered plastic, that would complete the closed loop with positive implications for the environment.