Production of steel annually amounts to about 1.8 billion tons with the number expected to double by 2050. Every ton of steel made produces 1.8 tons of carbon dioxide (CO2) contributing between 7 and 9% of greenhouse gas (GHG) emissions annually.

The methodology to make steel hasn’t changed much since the invention of the Bessemer Converter in 1856. The Converter is a vertical tower in which coking coal, iron ore and air are combined and heated to temperatures exceeding 1,200 Celsius (2,200 Fahrenheit) degrees.

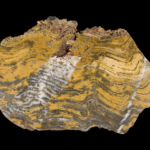

Coking coal is derived from metallurgical coals such as bituminous and anthracite varieties. The mining of these produces GHGs. Coking coal or coke serves two purposes. It supports the iron ore as it is introduced into the blast furnace using alternate layers, one of coke, and one of iron ore. Enough air pockets are left for the carbon to react with oxygen flowing through the furnace. The temperature rises another 300 Celsius (over 600 Fahrenheit) because of the reaction (hence the name reaction chamber) to reach iron’s melting point. The liquid iron then drains through the bottom of the tower. The air rises to the top containing significant amounts of CO2 and other GHGs.

Another steel-making method uses electric arc furnaces (EAFs). EAFs first appeared in Europe in 1879. Today, American steelmakers produce 40% of their production, mostly stainless and tool steel using EAFs which emit up to 89% fewer GHGs per metric ton than the previously described blast furnace methods. EAFs get used more to recycle scrap steel and have one other benefit. The electricity needed can come from renewable energy sources. So, all in all, a better choice for the entire steelmaking industry if reducing GHGs were a high priority.

But can steelmakers do even better by switching to something new?

Closed-Loop Carbon Recycling

A modified method of steelmaking that can be added to traditional blast furnaces has been invented. Devised by researchers from the University of Birmingham (U.K.) and the University of Science & Technology in Beijing (China), their closed-loop carbon recycling process eliminates up to 90% of the coking coal needed in blast furnaces. And since blast furnaces still represent where the bulk of steel is manufactured, this would be a good thing. The trick is the addition of a second reaction chamber.

In the first chamber, the process removes most of the coke and instead injects CO2 into the iron ore. Once it turns to liquid the CO2 then rises to the top of the chamber where a splitter turns it into oxygen and carbon monoxide (CO).

The second reaction chamber containing crystalline perovskite absorbs the oxygen while the CO is fed back into the furnace. The oxygen is released from the perovskite and the process repeats.

This novel steel-making process has recently been featured in an article appearing in the Journal of Cleaner Production.

Can Hydrogen Replace Coke In Steelmaking?

A process called direct reduction is used to make steel with hydrogen. Today most of the hydrogen produced comes from natural gas which puts hydrogen on the wrong side of the GHG emissions meter. But if hydrogen were to be produced from water then the gas and oxygen produced could feed reaction chambers to produce low-GHG steel. One company in Sweden, SSAB, has started producing what it calls fossil-free green steel using hydrogen and electrolyzers that convert water to get the gas. Volvo is its first customer. A second steel plant adopting the technology is to be built and become operational by 2024. And a Finnish company is also about to make a similar investment.

The key to the green hydrogen transition is reflected by electrolyzer demand which is expected to grow from $5 billion US shipped in 2021 at a rate of 33% through 2030. That should make green hydrogen fuel for reducing iron ore to produce high-end steel products viable.

The Steel Industry is at a Crossroads

The traditional way of making steel in light of its anthropogenic climate change impact calls for reinvention. Whether closed-loop carbon recycling or green-hydrogen direct reduction become the future methods by which the world satisfies the growing demand for steel-based products, it would seem appropriate that coke-based blast furnace technologies that will be almost two centuries old in 2050, should end. Those who take a leadership role in the industry, and governments need to make this happen.