This week’s five stories look at:

- Quantum Computers Go Commercial

- NASA 3D Prints Rocket Engine Parts

- Indian Company Starts Shipping a $25 Tablet Computer

- Conductive Plastic Skin Heals Itself

- Self-Assembling Polymers: The Next Breakthrough in Hard Drive Technology

Quantum Computers Go Commercial

D-Wave, a Vancouver, British Columbia-based company, has shipped its first generation of quantum computers to clients. Its clients include Google, Lockheed Martin, University of Southern California, and Harvard University. In October, Jeff Bezos, the founder of Amazon, invested through his venture capital firm $30 million in the company. That’s quite an endorsement of the company’s efforts in developing what is perceived to be a dimensional leap in computing.

Traditionally quantum computer designers have used the typical logic gates model. D-Wave’s approach is different. The model is adiabatic or quantum annealing. Quantum bits, known as qubits, shift from superposition to traditional computer states. They are not limited to two states, “0” or “1” and can do many calculations in the same amount of time as a traditional computer does one. For additional understanding on quantum computing I refer you to previous published blogs on the subject.

D-Wave’s latest quantum computer uses a 512-qubit processor and expects to quadruple the number of qubits every two years. Researchers believe that D-Wave computers with this kind of horsepower will be capable of solving problems that no other computing technology can touch.

NASA Uses a 3D Printer to Build Rocket Engine Parts

The Space Launch System, NASA’s heavy lift technology, is getting some of its parts from a 3D printer, the M2 Cusing Machine, installed in the Marshall Space Flight Center in Huntsville, Alabama. The first test piece is a rocket engine part that normally requires multiple pieces to be welded together. Using the 3D printer and a finely powdered nickel-based alloy, the printer created a duct for a rocket engine gas generator. A difficult part to make, the test piece met the minimal acceptable range in strength requirements although it wasn’t considered as strong as a comparably forged and milled product. The big advantage of the 3D printer – no welds which means no potential structural points of failure. NASA intends to make other parts that have complex geometries where welding of multiple pieces in the past was the only option.

India Delivers on a $25 Android 4.0 Tablet

Promising Internet for the billion plus of India, the government has taken steps to contract development of an inexpensive tablet. It’s called the Aakash 2. Datawind, a British company, is the builder. Commercially you can buy under its alternative brand name, the UbiSlate 7Ci for approximately $80. But the Indian government is subsidizing the educational price so that students pay 1,130 rupees or $21 US.

This is the second attempt at launching Aakash. The first time in 2011 it had the Android 2.2 operating system, and the device was slow, the battery poor and the touch screen unresponsive. In version 2 Aakash has been significantly upgraded with a 1 GHz Cortex-A8 processor, 512 Megabytes of RAM, 4 Gigabytes of flash storage, the Android 4.0.3 operating system, built-in WiFi, a front-facing VGA camera and a multi-touch responsive screen interface. Today only a small percentage of Indians have access to the Internet. But the government plans to buy 5 million units to kick start an Internet revolution throughout the country.

For Future Androids a Plastic Skin that Heals Itself

In the November issue of Nature Nanotechnology, research scientists at Stanford University, revealed they have created a self-healing polymer that can serve as synthetic skin. For Star Trek’s Data and the androids of the Terminator films this gives them a human-like experience, skin that self-heals and through its piezoresistive characteristics provides a sense of touch.

The material is a supra-molecular organic polymer with embedded nickel nano particles the size of individual atoms. When cut it repeatedly restores itself gaining its original integrity and conductive capability. The current version lacks elasticity but researchers hope to add the ability to stretch it in the next generation. Embedded with electronics this new skin can be incorporated into wearable medical devices such as monitors, or provide prosthetic wearers with arms and legs that are touch sensitive.

Self-Assembling Polymers: The Next Breakthrough in Hard Drive Technology

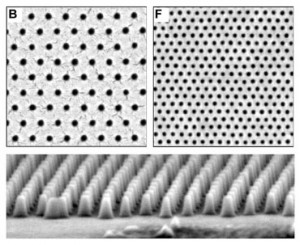

Polymers aren’t just good for making artificial skin. A research team at the University of Texas in Austin is using the material to increase the amount of data that can be stored on hard drives. As reported in this month’s edition of the journal Science, using a self-assembling polymer first pioneered at MIT and University of Wisconsin, the scientists have created nano-scale polymer structures that insulate magnetic elements allowing much greater crowding of data. The polymers contain maleic anhydride and two other components that when baked quickly form regular nano-scale patterns. Current drives allow a terabyte per 6.5 square centimeters (about one square inch). The new polymer increases that density by a factor of five. HGST, a Western Digital company, is testing the new material with plans to use it in its disk drive manufacturing.

A Postscript

This week I welcomed my first guest blogger here at 21st Century Tech Blog. I hope you enjoyed this change of pace. I also introduced in the last two weeks “Gizmos and Gadgets” which will become a regular feature of this blog to go along with features, updates and weekly headlines.

Traffic continues to climb with the hope that we can reach 10,000 monthly visitors by the New Year. So you can help me if you are a regular reader by letting others know about 21st Century Tech and why they should visit.

Once again, thank you for dropping by.

– Len Rosen