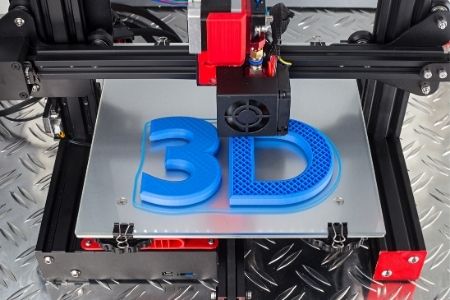

What is 3D printing, also described as additive or augmented manufacturing? It is a process by which digitally-rendered drawings and schematics can be translated into a finished object using a printer capable of producing three-dimensional structures. The printheads use inks made from metals, plastics, ceramics, glass, rubber, leather, stem cells, and almost anything else you can liquify. So there is no end to what you can create, whether you’re printing a figurine, a smartphone case, a doorstop, a wrench, or replacement parts.

Picking the right 3D printer for your needs and budget is a bit of a challenge because these devices come in a wide array of sizes, prices, and capabilities. And the printers also incorporate some different technologies. So if you are contemplating purchasing a 3D printer the following may prove helpful.

- Know what you want to print before you buy. There’s a huge variance between 3D printing gadgets and large industrial-scale production requirements for parts. The printing of parts today is becoming common at many manufacturing sites from automotive plants to parts for rockets. There are numerous reasons why industry leaders have moved to 3D printers to make parts. Instant customization, reduced warehousing of inventory, lower costs, and convenience are cited most often

- Identify your printing style. Many hobbyists use what is known as a Fused Deposition Model (FDM) printer. These printers extrude hot materials and plastic filaments to create 3D objects. Other printers use vats of liquid resin. Yet again others include Digital Light Processing (DLP), Stereolithography (SLA), and Selective Laser Sintering (SLS), the latter, which uses powder instead of resin.

- Look for safety features. A good example can be seen in FDM printers that cool the nozzle and heated bed once a job is done. Some printers move the nozzle away from the object when you pause the job or the print finishes, preventing heat damage and excess filament from forming.

- Resolution is important. Resolutions are measured in microns (a unit of length that is one-millionth of a meter), with resin-based printers being on the high end at 100 microns and FDM machines on the low end at 25 microns. The resolution of your final print can easily be adjusted with FDM printers. Resin printers are limited by the accuracy of their lasers. When choosing a printer that is easy to adjust, look for a higher number of microns in the specifications.

- Look for high-quality features. A few high-quality features that can be overlooked will change your 3D printing experience. Keep an eye out for things like touchscreen user interfaces, data filament support, and heated glass beds. Even something as simple as build volume or how much room you have to print can make a printer worth the investment.

- Good support. Look at the manufacturer’s customer support. Does the company have dedicated professional customer service to support its user base, or is it just a Facebook group? This can be the make-or-break difference between good 3D printing experiences and a bad ones.

I hope these tips help before you decide to invest in a 3D printer. From industrial to personal use, it’s important not to overspend, and it is equally important to know that the printer you choose will have the right features to produce the end result you seek.