Doesn’t this headline sound like a fantasy? Well, it’s not according to two professors at Korea’s Pohang University of Science and Technology (POSTECH). The range limitations of current lithium-ion battery packs are determined by the efficiency of their design and the materials used. Most lithium batteries use graphite anodes. Changing from graphite to silicon has always been a dream because an anode made from it would greatly increase electric vehicle range. But silicon doesn’t seem to like the chemicals used in lithium-ion batteries causing it to expand when used as anode material.

Professors Soojin Park and Youn Soo Kim at POSTECH have been working with Professor Jaegeon Ryu at Sogang University to overcome the problem of using silicon anodes. They have invented a polymer binding material that protects silicon anodes in lithium-ion batteries from expanding and forming dendrites that dramatically limit charge retention and battery life. The result is a lithium battery with up to ten times the charge capacity of those currently being used. That means instead of the 300 to 500-kilometre range limitation in EVs, the distances that can be travelled between charges can be as much as 3,000 kilometres apart, roughly the distance between Toronto, Ontario and Los Angeles, California.

It has been known for some time that silicon used in anodes provides higher energy densities than graphite. The problem has been their reaction within the battery. Before Park and Kim, research on silicon in battery anodes focused on chemical crosslinking and hydrogen bonding. The limitation to bonding was that once used the hydrogen bonds would break and could not be restored.

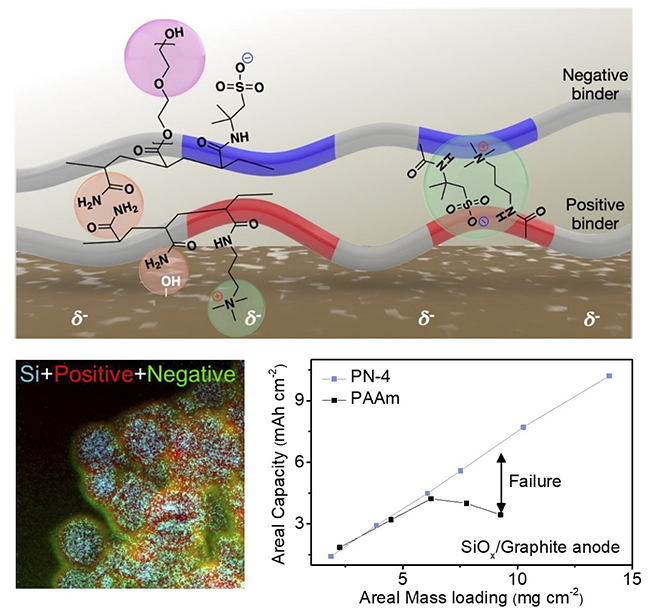

So the two developed a polymer that could use hydrogen bonding that was reversible. The polymer created layers in the anode with alternatively positive and negative charges (see illustration below). The two then added polyethylene glycol to regulate diffusion to create a thick high-capacity electrode.

Soojin Park notes “The research holds the potential to significantly increase the energy density of lithium-ion batteries through the incorporation of high-capacity anode materials, thereby extending the driving range of electric vehicles.”

Amazingly, we are not talking about doubling the range of current EVs outfitted with silicon-anode lithium batteries but increasing it by tenfold.

This is not the first advancement this duo has produced in creating next-generation lithium-ion battery technology. At the 2024 Consumer Electronics Show in Las Vegas, they demonstrated using micro silicon particles and gel polymer electrolytes in a battery to provide a 40% improvement over conventional battery performance using liquid electrolytes.

The two are part of a team of researchers working in POSTECH’s Polymer-based Energy Materials Lab. The goal is to develop polymer-based materials for smartphones, laptops and EVs. They have published work on batteries that stretch like rubber, ultra-thin, lens-like batteries and paper-like foldable batteries. The foldable batteries replace aluminum and copper with polymer nanomaterials that can be folded and unfolded a thousand times but doesn’t break when struck by a hammer. The high-capacity silicon anodes represent their latest inventions designed to improve performance for next-generation batteries.

Their research on batteries reflects a growing need for our global industries, utilities, and the transportation sector to transition from fossil fuels to electrification. Current projected battery unit sales are expected to grow from 17.5 million and US $48.7 billion in 2024 to 40 million and $71.5 billion in 2030. Battery manufacturing capacity is expected to reach 9 Terrawatt hours by 2030.

The battle for battery supremacy is on with Korea’s POSTECH joining other academic centres across the world. In Korea, POSTECH is joined by Seoul National, Sungkyunkwan, Chung-Ang University and KAIST, the Korea Advanced Institute of Science and Technology.

What other countries have joined the race to battery and electrification breakthroughs in the 21st century? I have discovered several which I list here in alphabetical order.

- Canada research is at the University of Waterloo’s Centre for Advanced Photovoltaic Devices and Systems (CAPDS, Nova Scotia’s Dalhousie University, Alberta’s University of Calgary and the University of Alberta, and the Okanagan Battery Innovation Centre at the University of British Columbia.

- China research is at Beijing-based CABRI and the Ningbo Institute of Materials Technology and Engineering in Zhejiang Province.

- India research is being done at the Indian Institutes of Technology located in Madras and Mumbai, as well as Shiv Nadar University.

- Israel research is led by Bar-Ilan University, Tel Aviv University and the Technion in a collaborative research effort called INREP, the Israel National Research Center for Electrochemical Propulsion.

- Japan battery technology research is found at the Tokyo University of Science, Yokohama National University and Tohoku University in Sendai.

- United States research is found across the country with the leading centres at the Oak Ridge National Laboratory in Tennessee, the Argonne National Laboratory in Illinois, Stanford University, the University of California at San Diego (UCSD), the University of Maryland, the Pacific Northwest National Laboratory in Washington state, and Philadelphia’s Temple University.

EV sales, including all battery and battery plug-in hybrids, are expected to hit the 16.7 million mark in 2024, up from 13.9 million in 2023. So, although manufacturers and the media have reported a drop-off in demand (from 60% to 33% growth year to year), the figures remain solid and going in the right direction. Just ask General Motors, which is doubling down on EVs and battery technologies.

Postscript

When I published this article last week, NEO Battery Materials had not yet announced a new joint venture with Lotus Energy Recycling to recover silicon from photovoltaic cells and solar panels for supplying lithium-ion batteries with silicon anodes. That announcement came on October 21, 2024.

NEO is a Canadian-based battery material technology company and Lotus Energy Recycling is Australian-based and features proprietary technology for recovering highly pure silicon. The two plan to build a facility in Canada to collect, dismantle and recycle end-of-life solar panels and photovoltaics.

With operations like this one pending, silicon anodes in lithium-ion batteries hold great promise for the future of EVs and lithium battery storage technology in general.