January 9, 2016 – Small molten salt nuclear reactors may become a part of the energy mix by the mid-2020s if Terrestrial Energy has its way. The company, based in Oakville, Ontario, just received $10 million in a new funding round to continue development of its Integral Molten Salt Reactor (IMSR).

The goal, to deploy an IMSR sometime in the 2020s, demonstrating the utility of the technology for both on and off power generation. Each reactor costs no more than a coal-fired power plant but produces zero emissions. The price tag is considerably less than any nuclear power plant in operation today.

Back in April of 2013 I wrote about new initiatives coming out of Canada related to fusion and fission reactor technology. One of the companies I wrote about at that time was a new startup, Terrestrial Energy. Now into its third year the company is working in partnership with Oak Ridge National Laboratory in Tennessee. That’s where the first prototype molten salt reactors were developed in the 1960s. But the designs never made it to commercial production. It may have been because there was more than agenda in the nuclear power industry. It wasn’t just about electricity generation, it was also about creating weapon’s grade fissile materials.

Now may be the time for IMSRs, an opportunity for the nuclear power industry to contribute a much better solution to the market while helping the planet to lower its collective carbon footprint.

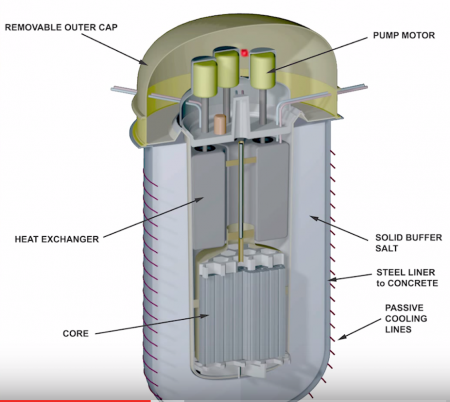

How does an IMSR work? Where solid fuels are used in conventional nuclear power plants and when spent become a storage challenge, IMSRs use liquid fuel. This has distinct advantages with the liquid serving dual purposes – both as fuel and coolant. That means an IMSR can never have a meltdown.

An IMSR doesn’t need expensive pressure containment vessels to contain the nuclear reaction. Its fuel is fully recyclable. It uses uranium which is the heating source for the liquid molten fluoride or chloride salts. The heat is not only used to create steam to drive turbines, it can also be used for industrial manufacturing processes. Uranium used by an IMSR is less enriched than current nuclear technology. When it degrades it has no value for making nuclear weapons. It can even use spent uranium and plutonium from other nuclear power plants as a fuel source.

Each IMSR reactor core (seen in the picture below) would be manufactured on a production line, and then shipped to an installation site. Each core would be completely sealed and designed to operate for 7 years. Once spent it would be taken off line and replaced by a new one. And because the core’s form factor is small, a power plant could have several IMSRs operating in parallel making it easy to switch one out and replace without shutting down the entire facility. At end of life a core unit would be left to cool down and then stored with the denatured uranium permanently sealed in its own containment vessel.

The flexibility that IMSR brings to nuclear power means a single core could power a microgrid. Multiple IMSRs could power a city. And an off grid IMSR could power remote sites without the need for transmission towers and lines.

One wonders why it took over fifty years for industry to take IMSR from the laboratories of Oak Ridge and turn it into a commercial technology?

States James Reinsch, former President of Bechtel Nuclear and a member of the board of two nuclear power plants, “market need has never been greater for true game-changing energy innovation……nuclear power is recognized as probably the only energy technology today that has the scale to displace polluting energy sources without sacrificing cost-competitiveness and perpetuating energy poverty for billions.”

For countries seeking a transition to a low carbon economy IMSR looks like a good investment bet.

[…] reactors may become a part of the energy mix by the mid-2020s if Terrestrial Energy has its way. [3] If one wants to build a breeder reactor using uranium, or in other words, if one wants to build a […]