July 21, 2014 – I remain skeptical about the economics of industrial technologies for carbon capture. Almost every project started has been heavily subsidized by government. But for the operators without government subsidy there seems to be no return on investment. First of all, all existing industrial carbon capture technologies are expensive to implement. Second, once installed in the outflow processes of a typical coal-fired power plant they require additional energy to operate which means the utility actually has to burn more coal to capture the carbon.

Enter the University of Kentucky and its Center for Applied Energy Research. At the E.W. Brown power plant (seen below), located in Harrodsburg, Kentucky, a new technology for carbon capture may prove to be an industry game changer.

Typical carbon capture processes recover the CO2 from the outflow stack in a power plant. This is done by spraying a liquid solvent into the outflow. The solvent traps CO2. As much as 98% of the gas can be scrubbed from the chimney emissions this way. But what to do with the CO2-solvent mix.

Carbon capture systems are designed to reverse the process to restore the solvent while releasing the CO2 into a trap of some kind. That trap is usually a storage tank. From there added energy is needed to compress and pump the carbon underground. If located over a stable sandstone formation, the captured carbon can begin to bind with the rock turning it into limestone which permanently traps the carbon. These processes produce waste heat as a byproduct and because they need additional energy require the plant to burn more coal.

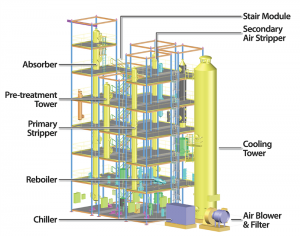

The University of Kentucky process, however, attempts to integrate carbon capture into the power plant, rather than have it as an add-on process at the end point. The schematic below shows the carbon capture part of the E.W. Brown plant installed in Harrodsburg. The heat generated during carbon capture is in itself captured for reuse. A second step in the interaction between solvent and the CO2 produces even higher rates of carbon removal.

The 2 Megawatt unit cost $19.5 million U.S. and will be operated by LG&E and KU ODP. Other project participants include the University of Kentucky, Kentucky Power, Duke Energy, and the U.S. Federal Department of Energy, the latter contributing $15 million to the project.

I truly hope this new carbon capture technology succeeds. But would it have legs if it weren’t for a 75% subsidy from the federal government? I state this because that seems to be the only reason private enterprise engages in carbon capture and sequestration projects – when they get federal, state, or in the case of Canada, provincial money to offset potential losses.

If a carbon tax were implemented, however, instead of the cash carrot incentive which is the present practice, power utility companies would be compelled to implement carbon capture or pay for the pollutants they discharge. But here in North America only a few jurisdictions have legislated a carbon tax, a critical mistake by our governments if they want to make a serious dent in our carbon footprint.