Before the COVID-19 pandemic temporarily shut down surgical procedures I had been scheduled for a left knee replacement in April of 2020. I had my pre-operative checkup a few weeks earlier and then hospitals stopped doing “elective” procedures as the pandemic hit Toronto with full force.

Before agreeing to knee replacement, I had researched stem cell cartilage replacement therapy to the nth degree but that option eluded me. Although delayed and under total isolation conditions the operation was performed on July 15, 2020. Two days later I was home to recover and rehab with a physiotherapist who virtually visited me over Zoom as I exercised my way back to full mobility without a walker or cane in three months.

The osteoarthritis that caused my left knee so much grief and pain is a thing of the past now, but my interest in less invasive and minimal surgical knee interventions remains high. I have osteoarthritis in my right knee but no pain so I assume I can live with that condition for many more years. Should I need to do something about it, there is the promise coming from a four-year joint project in Germany involving the Fraunhofer Institute for Applied Polymer Research and the Brandenburg University of Technology Cottbus-Senftenberg BTU. The research is focused on producing personalized 3D-printed personalized cartilage-cell-embedded implants to restore knee function.

Before my knee operation, I had asked my surgeon why cartilage replacement therapy had yet to evolve for use in treating bum knees. He laughed about what the prospect of developing an alternative to surgery would do to his job but also described the considerable challenges the research had yet to resolve.

I mentioned I had been following work being done in Germany, Chicago, and at the Mayo Clinic. The latter has the RECLAIM Project which was at the time still at its earliest stages. RECLAIM stands for Recycled CartiLage Auto/allo IMplantation and it remains a work in progress.

My surgeon told me that growing personalized cartilage cells wasn’t the problem. The challenge was being able to put the cells in the right place and have them adhere and grow to fit the exact shape of the joint. That’s when he brought up the challenge of growing collagen.

Where cartilage provides the lubricated smooth surface and shock absorbers our knee joints need, it is collagen that gives cartilage its structural framework and tensile strength. Without collagen, cartilage has no framework upon which to attach.

In the past harvesting cartilage from other parts of the body and inserting it into the knee has been tried with limited success. Collagen, however, has remained the unresolved challenge.

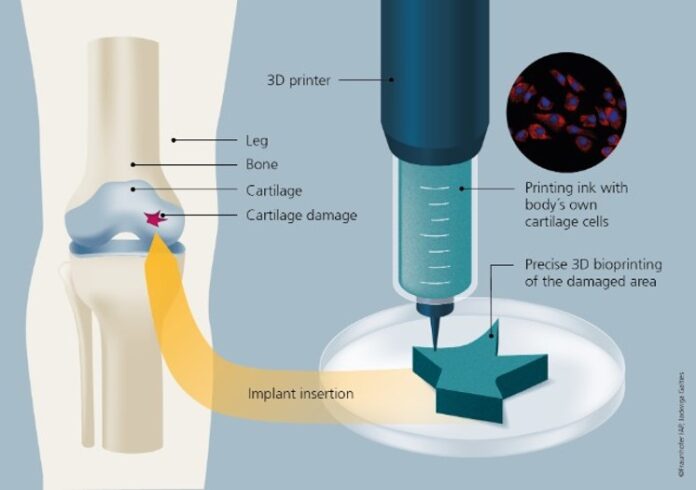

What the German-based research project is proposing involves embedding host cartilage cells into a glycopolymer hydrogel and 3D printing multiple layers of the mix on the joint surfaces to recreate what the cartilage and collagen combination would do naturally.

The process is called BioPol-3D. In an August 21, 2024 Fraunhofer press release, Professor Ursula Anderer, who holds the Chair for Cell Biology and Tissue Engineering states, “Our approach to printing the cartilage cells goes beyond conventional methods because we mould the biological component – the cartilage cells – directly. In other words, we don’t first print a scaffold on which cells are later placed.” That solves the collagen challenge.

It remains a work in progress to get the printable ink mix just right so that the living cartilage cells remain viable throughout the layering process and after. Anderer notes “the inks must be biocompatible and biodegradable” while the printing itself must produce “the desired cartilage shape” with “a high degree of stability and strength.” The goal is “to establish an advanced 3D cell culture for the treatment of cartilage damage and at the same time revolutionize the production of such moulded bodies through additive manufacturing.”

I wonder if my knee surgeon has seen the work being done at the Fraunhofer and Brandenburg. If it is ready for clinical trials and perfected before the end of the decade, I am sure he will become aware because knee replacement will never be the same as medical 3D-printing comes of age in the third decade of the 21st century.