Two stories caught my eye in the last week. The first came from research at Oregon State University on a novel nanomaterial that efficiently removes carbon dioxide (CO2) even in humid environments.

The second is a follow-up to an ongoing story that involves the Canadian company, Carbon Engineering. Last year, I wrote about this company entering into a contract with Occidental Petroleum to deploy between 70 and 135 of the former’s CO2 Direct Air Capture (DAC) plants. Well, it appears that the relationship has turned into an acquisition. But more about that later. First, let’s look at what Oregon State researchers have discovered.

Cost-Effective Nanomaterial Could Efficiently Remove CO2 Emissions

Findings from Oregon State University have been published in the journal Cell Reports Physical Science revealing a novel nanomaterial that can filter CO2 from industrial pollutants.

This technology could be implemented in fossil-fuel-burning thermal power plants and industrial emitters like cement, steel and aluminum refiners, all significant contributors of greenhouse gas (GHG) emissions responsible for global warming.

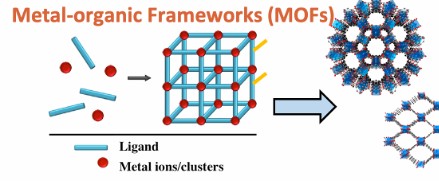

The material is a metal-organic framework (MOF) which can intercept CO2 molecules through adsorption when exposed to smokestack gasses. See an illustration of what MOFs look like below.

States Kyriakos Stylianou, Assistant Professor at Oregon State, and study lead, “MOFs have shown a lot of promise for carbon capture because of their porosity and their structural versatility, but synthesizing them often means using reagents that are costly both economically and environmentally.” He further notes that water in smokestacks complicates removal requiring the flue gasses to be dried before the CO2 can be captured. The solution was to invent a MOF to address current material limitations that include:

- high cost,

- poor selectivity for CO2,

- low stability in humid conditions,

- and low CO2 uptake capacities.

MOFs as seen in the above illustration are designed for porosity. They consist of crystalline, positively charged aluminum ions with “linker” molecules called ligands made of benzene-1,2,4, and 5-tetracarboxylic acid. The structure is a nanosized, spongelike cage that Stylianou’s MaD Lab has built to capture CO2.

Stylianou notes that it is “an outstanding candidate for wet post-combustion carbon capture applications” which makes it ideal for use in coal-fired thermal power plants that use water in their flue scrubbing process. The MOF, Stylaniou continues, is “cost-effective with exceptional separation performance and can be regenerated and reused at least three times with comparable uptake capacities.”

How many coal-fired thermal power plants are operational today around the globe?

- More than 8,500 are still out there despite efforts to convert to low-carbon emission energy-generating alternatives.

How many cement plants are there?

- Over 2,600 with almost all producing significant GHGs.

And how many steel and aluminum plants?

- Over 550 steel and more than 200 aluminum smelters globally, with most emitting significant GHGs.

If a good percentage of these were to adopt this MOF technology, it could impact our fight to mitigate climate change significantly.

Occidental Petroleum Acquires Carbon Engineering

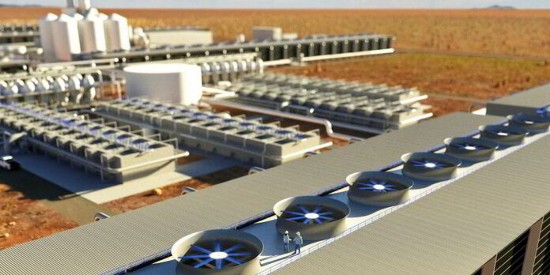

Carbon Engineering and Occidental Petroleum, through its subsidiary 1PointFive, entered into a partnership in 2022 to deploy between 70 and 135 Direct Air Capture (DAC) plants like the one seen in the illustration below, each with the capacity to remove and store a megaton of CO2 annually.

It would seem that the partnership is going well with Occidental agreeing to acquire Carbon Engineering outright for the sum of US $1.1 billion. The money will be used to accelerate scaling the technology to meet global demand. With the acquisition announcement, the company announced a revised number of DAC plants that will capture CO2 directly from ambient air and either bury it underground or use it to make new products such as concrete and aviation fuel.

Why is this acquisition significant?

Occidental has a market value of $58.04 Billion and is a major oil producer in Texas where 30 of the proposed DAC plants will be located. The company rivals Chevron, Exxon Mobil, Royal Dutch Shell and BP in terms of fossil fuel production.

Why DAC as opposed to in-situ carbon capture at production and refining sites? DAC technology can be placed anywhere there is access to renewable energy and underground storage. It is, therefore, not tied to any existing energy-generating infrastructure which provides great flexibility.

But 100 DAC plants, each capturing a megaton of CO2 annually represent 100 megatons or 0.1 gigatons. Climate researchers estimate that we need to draw down CO2 emissions by 10 gigatons annually from the atmosphere and oceans to keep global warming to 1.5 Celsius (2.7 Fahrenheit) degrees. So that means we need 10,000 DAC plants of the size Occidental is intending to deploy to get to reverse the upward climb of global atmospheric and ocean temperatures. Occidental alone will not get us to that goal. The rest of the big fossil fuel players who still wish to be in the oil business, therefore, need to pony up.