Graphite is the substance we call lead in our pencils. The word is derived from the Greek verb meaning “to write.” Of course it’s not lead at all but a mineral all on its own. Graphite’s chemical formula is C which tells you it is derived from carbon that has been altered through metamorphic processes. That means it has been exposed to heat, pressure or water, the major contributors to metamorphic mineralization.

That’s why you find graphite in pegmatite, a rock found where magma or lava has intruded into other rocks causing a chemical and crystalline alteration. As a young boy with rock hammer in hand I remember collecting pegmatite and schist samples as I wandered through Ontario. You can see a sample of schist below.

Graphite serves many purposes today besides its use in pencils.

- It is the largest component in in lithium-ion batteries.

- It can be found in solar panels.

- It is the material in the control rods that contain nuclear fission in power reactors.

- It is suspended in oil and used as a lubricant in machinery because of its low friction characteristics.

- It is the material used to make crucibles, the containers in which aluminum, brass and other non-ferrous metals are smelted.

- It is used in paint where its water repellent chemistry provides a protective coating.

- It can be found in brake linings.

- It is a material used in manufacturing electronic circuits.

- In foil form it gets used in electronic devices serving as a heat sink to cool the electronics during operations.

- It is the source of graphene, the lightest and strongest known material on Earth.

The Miracle Material: Graphene

Graphene is a nanomaterial first discovered in 2004 at the University of Manchester in the United Kingdom. Graphene is described as a thin film material and consists of a single layer of carbon atoms bonded in a honeycomb lattice. Electrons that move through graphite encounter resistance but when they move through graphene there is virtually no resistance. That makes graphene a super material that can be used for many industrial applications including:

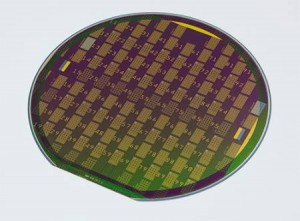

Transistors

Graphene transistors run at higher frequencies than any existing silicon transistor we use today. In fact a graphene transistor makes it possible to build computer processors capable of speeds of 10-20GHz. I’m typing on a Dell Computer running at 2.93 GHz and can only imagine what it would be like to use a system built using graphene. Not only would it be ultra-fast it would also be small, a form factor smaller than a paperback novel.

Gas Sensors

Because graphene is one-atom thick and forms a lattice it is capable of detecting the presence of a minute traces of hazardous substances. A graphene-built gas sensor would detect amounts as small as a single atom or molecule.

Thin Resistant Coatings

Graphite is used in impermeable paints. But graphene can be used to thinly coat pipes carrying highly corrosive acids or reactive alkali such as sulphuric acid or ammonia.

Carbon Nanotubes

Graphene is the material of carbon nanotubes – the stuff of space elevators. There are many other applications including lighting, electron microscopy, antistatic materials, radar-absorbing materials, electrolytes in batteries and fuel cells, conductive adhesives, thermal materials, fabric, catalysts, prosthetics and frameworks for biomedical applications such as neuron growth and regeneration.

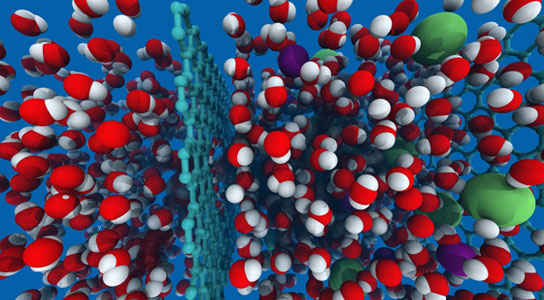

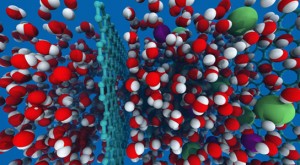

Desalinization Filters

Massachusetts Institute of Technology engineers are using thin-film graphene membranes with strategically located pores just large enough to allow water molecules to pass through while resisting sodium and chlorine salt molecules. The strength of the graphene membranes, a mere one atom thick, can withstand the pressure of the osmotic process providing much faster flow through. This technological capability will reduce the cost of desalinization and make freshwater available for many parts of the world currently experiencing water stress.

Graphene Challenges – Make it Easier and Cheaper to Produce

When graphene was first discovered it cost a lot of money to create a single thin sheet. But new techniques are being pioneered at the University of Arkansas with the announcement last week of a breakthrough in controlling graphite to graphene production.

Up until now transitioning graphite to graphene was random. But the researchers have developed a technique called electrostatic manipulation scanning tunneling microscopy. This new technology uses a moving surface to migrate the graphene from graphite. The next step will be to scale this to commercial production levels.