July 16, 2019 – NASA’s Space Technology Mission Directorate (STMD) is focused on pioneering new technologies to make access to and operations in space more attainable and cost manageable. STMD encourages competition among commercial vendors based on goals it establishes for technological innovation in space to create new inventions and a space economy.

One of the challenges of launching from Earth is the gravity well that requires massive amounts of energy to insert large payloads into orbit. Learning from the development of the International Space Station (ISS) and the modular approach taken to assembly, NASA wants to go one better by printing space structures from raw materials shipped to orbit, or acquired from harvesting the content of Near-Earth asteroids.

For some time now NASA has had on board the ISS, a working 3D printer for creating tools and spare parts to be used on the station. But the next bold step is to manufacture spacecraft in orbit using 3D printing.

Jim Reuter, Associate Administrator at STMD describes in-space robotic manufacturing and assembly as “unquestionable game-changers and fundamental….for future space exploration.”

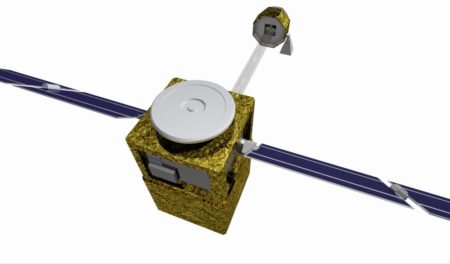

In its latest press release, NASA describes the purpose and goals of a $73.3 million USD award given to California-based Made In Space, to demonstrate Archinaut One, a spacecraft that will 3D-print two 10-meter (approximately 32-foot) solar arrays when in orbit.

A ground demonstration of Archinaut’s capability has already succeeded using a thermal vacuum chamber at the Ames Research Center in California. This was done in 2016. But now the true test of the technology will come when New Zealand’s Rocket Lab launches Archinaut into Earth orbit as early as 2022.

How Does This Change Humanity’s Future in Space?

Made In Space, the company NASA is funding has developed a mission to create a space environment where humans can manufacture what is needed in space while in space, and to make living and working in the environment commonplace.

Its AMF 3D printer is currently being used on ISS and has demonstrated its ability to manufacture complex, fine precision objects using aerospace-grade materials. But Archinaut takes 3D-printing technology to the next stage: moving it outside the controlled environment of ISS, and engaging in the building of large structures on demand in the near vacuum of space.

This could mean the beginning of an entirely new industry and field of design, architecting space structures through autonomous robotic technologies like beam builders which is what Archinaut One is all about. Instead of designing space structures to fit the confined payload limits of current launch vehicles, through Archinaut and its successors we will be able to assemble the backbone structures of large frameworks and arrays, build even bigger space telescopes, and create large human in-space habitations. We will be able to assemble and build spacecraft, repurpose them as needed, and tinker with existing designs to optimize their use in space.

Once Archinaut has proven itself it can become the backbone for our planet’s space infrastructure. And instead of using ground-based materials, we can begin to harvest what we need from asteroids, or the Moon (a much lower gravity well for launches than Earth), building fully integrated assemblies and structures that will be a better fit and less expensive than that which we build on Earth. Functional components from antennae, sensors, solar panels, and even wiring will no longer be manufactured on Earth because Archinaut and its successors will manufacture, maintain and refurbish anything we need in the outer space environment.

Archinaut’s successors will be the builders of the first truly interplanetary and interstellar space ships to take humans or their artificial intelligent constructs to the farthest points in our Solar System and beyond. The beam builders of science fiction will have become a reality.