November 18, 2018 – On Saturday, November 17th, an Antares rocket launched a Cygnus spacecraft filled with tons of food, supplies, and scientific experiments destined for the International Space Station. It was the tenth Cygnus flight to the ISS and should arrive Monday morning. On board is the Refabricator, a combination 3D printer, and recycler that can take waste plastic and turn it into feedstock for the printer to create new items. Developed by Tethers Unlimited Inc., a Bothell, Washington company, the Refabricator will be used on board the station to make new parts, utensils and medical implements from plastic waste.

Tethers isn’t just limiting itself to fabricating stuff inside the ISS. They are working on something called SpiderFab, a fabricating system to build large structures in space from antennas to solar panels, to trusses. SpiderFab is being designed to build kilometer-length structures in space. One can imagine it being a beam builder for future space stations, or space radio telescopes stretching kilometers in length.

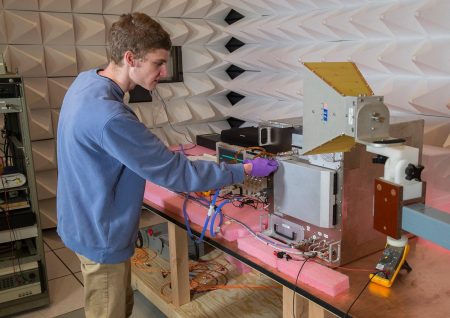

But getting back to the Refabricator, NASA describes it as a key component for its in-space manufacturing (ISM) technology. It functions as a closed-loop recycler taking waste plastic and turning it into high-quality 3D printer filament. The model being shipped to the ISS will demonstrate its effectiveness in microgravity with materials testing of specimens created from waste source materials. Initial test products will be returned to Tethers to check on the quality of the filament produced, the end products, and any potential degradation occurring during and after the printing process related to the space environment.

Refabricator is not the Star Trek replicator. But it is the first integrated plastic recycling system combined with a 3D printer. If successful the Refabricator will make it possible for those onboard the ISS to reduce waste that ends up being stored onboard the station before it can be disposed of in spacecraft like the Cygnus when returned to Earth. Less onboard waste means more room for the astronauts. Less onboard waste also means less needs to be shipped up to the ISS from Earth.

And the side benefit for us down on the planet surface is the Refabricator could turn one-time use plastic bags and bottles into new products eliminating millions of tons of waste that is turning our oceans into a sea of plastic.