December 26, 2016 – It is called the thermoelectric effect and we have known about since the early 1800s. It occurs when two different conducting materials maintained at different temperatures meet at a junction point. In electric circuits it occurs if there are two different conductors or a single conductor with a temperature gradient. So it would seem advantageous to convert waste heat or cold in industrial processes into electricity.

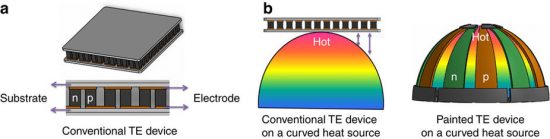

Researchers in Korea, at the Ulsan National Institute of Science and Technology (UNIST), set out to see if they could create a coating that could be applied to almost any shape to harvest energy using the thermoelectric effect. The coating is an inorganic thermoelectric paint that contains bismuth telluride and antimony telluride particles, both semiconducting materials. When applied to a metal surface the researchers generated power output of 4 milliwatts per square centimeter.

The results of the research can be found in the November 11 issue of Nature Communications. The literature describes high-performance, shape-engineerable thermoelectric painting which can be applied to flat or curved surfaces and capable of high output power. Alternately applying the two different semiconducting paint materials produced energy yields at temperature ranges from 25 to 125 Celsius (77 to 257 Fahrenheit) degrees. Best conductivity results occurred in the lower temperature range.

Why does the thermoelectric effect work so well with this new paint. The researchers believe it is the nature of the porosity of the material that makes this paint a highly efficient energy generator. With a 50 nanometer alternating application to a common surface the paint yielded considerable electrical output. Best results were achieved on curved surfaces.

What are the potential applications? Imagine applying the paint to a car exterior or a building to harvest the renewable energy produced.