February 11, 2018 – Yesterday I wrote about a new super wood that is stronger than steel. But overnight I received one of Peter Diamandis’ emails in which he described changes about to overtake construction that are equally exciting. We are indeed witnessing the beginning of a significant disruption in construction both in methods and materials. Sharing this with you from Samara, Costa Rica.

If you could design any structure, free of all constraints, what would you envision? Put aside today’s architectural limits. What home would you dream up?

Exponential technologies are converging and revolutionizing the way we design, build and inhabit everything.

The global construction industry is projected to surpass $10 trillion in 2020, and the total U.S. housing stock alone grew to $31.8 trillion last year. Both industries are ripe for massive disruption.

In this posting, I cover four key tech trends revolutionizing what is possible in architectural design and construction:

- New materials from unexpected sources

- Designs that adapt as you build

- Autonomous robot builders

- 3D and 4D printing

New Materials Enter Construction

For thousands of years, we’ve been constrained by the construction materials given to us by nature. We have built with bricks from clay and shale. We have used tree limbs for rooftops and beams. And we have mastered incredible structures with the use of cement. But construction materials are about to get a HUGE upgrade.

Here are the top three materials disrupting the future of construction:

1. Upcycled Materials: Imagine if you could turn the world’s greatest waste products into their most essential building blocks. Thanks to UCLA researchers at CO2NCRETE, we can already do this with carbon emissions. Today, concrete produces about 5% of all greenhouse gas (GHG) emissions. But what if concrete could instead, conserve greenhouse gas emissions by sequestering them in the material? CO2NCRETE does this by capturing carbon from smokestacks and combining it with lime to create a new type of cement. 3D printers then shape the upcycled concrete to build new structures. Once scaled up this upcycled concrete will turn the former greenhouse gas polluter into a future conserver.

Want to print houses from dirt? No problem. The Institute of Advanced Architecture of Catalonia (IAAC) can now turn any soil into a building material with three times the tensile strength of industrial clay. For developing regions the potential is massive. Using IAAC soil and 3D printers, houses can be built on site in the Developing World for as little as $1,000.

2. Nanomaterials: Nano- and micro-materials are ushering in a new era of smart, super-strong and self-charging buildings. While carbon nanotubes dramatically increase the strength-to-weight ratio of skyscrapers, revolutionizing their structural flexibility, nanomaterials don’t stop there. Several research teams are pioneering silicon nanoparticles to capture everyday light flowing through windows. Little solar cells at the edges of windows then harvest the energy to produce heat and light

At the U.S. National Renewable Energy Lab, researchers have developed smart windows as well that turn into solar panels when bathed in sunlight. These thermochromic windows can power buildings changing colour as they do. The colour change serves to keep the area behind the windows cooler.

3. Self-Healing Infrastructure: The U.S. Department of Transportation estimates a $542.6 billion backlog in infrastructure repairs alone across the entire country. Enter self-healing concrete.

Engineers at Delft University have developed bio-concrete that can repair its own cracks. As head researcher Henk Jonkers explains, “What makes this limestone-producing bacteria so special is that they are able to survive in concrete for more than 200 years and come into play when the concrete is damaged.…If cracks appear as a result of pressure on the concrete, the concrete will heal these cracks itself.”

But bio-concrete is one of a number of self-healing technologies that will soon be used by engineers and architects.

As futurist architecture firms start printing plastic and carbon-fiber houses using processes developed by companies like Branch Technology, self-healing plastics will become more common. And plastics will not be limited to use here on Earth. NASA engineers are pioneering a self-healing plastic that may prove vital to space missions, preventing habitat and ship ruptures in record speed.

Enhanced Design & Architecture

While incredible new materials transform what we build, artificial intelligence (AI) and virtual reality (VR) are revolutionizing how we design.

1. AI-Driven Design: In the past, if you wanted to build a high-rise, you needed a static, precise blueprint. Moving parts were not an option. Now, real-time, AI-aided Building Information Modeling (BIM) enable blueprints to learn and adapt to changing ground conditions, weather, equipment, and even new design ideas. In the future, AI will create the blueprints, optimize construction methods, breakthrough materials, and design features. AI may even recommend the IoT components to embed in our high-rises.

2. Virtual Reality Shaping Real Estate: VR is already reshaping the real estate shopping experience. But soon we won’t need the agents or even the need to go out to physically hunt for houses. You’ll be able to visit a house in a different city from the comfort of your living room and see how it looks with blue walls and your own home furniture?

VR is about to transform the real estate design process too. Imagine the possibilities: you design your company’s dream office using a BIM and allow your managers to walk around the virtually-finished space before it’s even built.

Building with Autonomous Robots

Designs and machinery won’t build us finished products on their own… or will they? Welcome to the new frontier of autonomous robot builders and skyscraper printers.

While robots have already started permeating the construction industry, what if they could construct buildings entirely autonomously?

Many are already tackling this challenge, using everything from flying robots to termite-like swarm constructors.

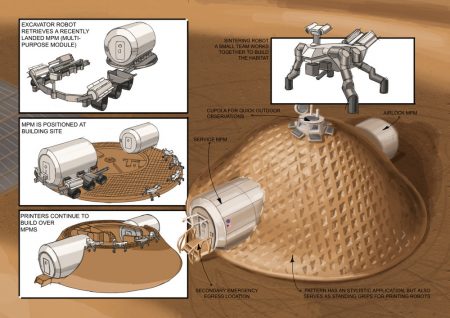

RoboticsX aims to send autonomous robot builders to Mars that can adapt to shifting ground conditions. CEO Peter Boras speaks of plans to scale up 3,000 collaborating robots in the hopes of building structures almost entirely unaided. The company’s X-1 Smart Industrial Robot can already collaborate with its colleagues, adapt tasks in real time, share its capabilities with other machines and perform predictive maintenance.

A team at Switzerland’s NCCR Digital Fabrication has also built a fabricator robot. Pre-programmed with design model data, the robot can build any steel-reinforced framework autonomously on-site.

Inspired by autonomously collaborative termites, Harvard robotics researchers have developed swarm construction robots that collaboratively build a programmed design, block-by-block, without centralized control.

Imagine the implications. Eliminating human safety concerns and unlocking the ability to build in any environment, autonomous robots will collaboratively build massive structures in space, or even in deep underwater habitats.

Using 3D and 4D Printers

The near future of construction will feature 3D printing which will help to redefine the way our buildings look, feel and even move.

You may have heard of the Chinese company WinSun Design Engineering Co., which recently printed 10 houses from recycled materials in 24 hours at a cost of about $4,800 each. Or Dutch studio DUS Architects, who used sustainable bioplastic to 3D print a full-size canal house in Amsterdam. [Both have been previously described in postings here at 21st Century Tech blog.]

They represent just the start. Companies like INNOprint can print an emergency shelter in 30 minutes. Other companies are finding ways to print unprecedented designs, like the never-ending looped house built using one massive robotic 3D printer.

But that’s just the start. Remember the magical moving staircases in the Harry Potter films? Turns out these may no longer be exclusive to the wizarding world. That’s because 4D printing can make such structures a reality. Born out of MIT’s Self-Assembly Lab, 4D printing involves 3D printed objects that reshape themselves and even self-assemble over time. These structures involve the use of 3D printed rigid and expandable materials sharing the same space. When the expandable materials encounter certain conditions, such as adding water or heat, they reshape and reposition the rigid parts of the structure. Thus 4D printed structures contain moving joints that can reshape an entire component like a staircase.