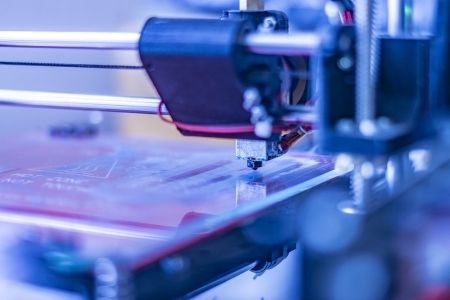

The term 3D printing refers to the ability to digitally model an object and render it into a computer-aided-design (CAD) drawing which can then be built using a specialized printer that creates objects that are three-dimensional. Applying it to the medical field can build replacement organs and tissue, customized prosthetics and implants, and detailed anatomical models. 3D printing can even be used to produce pharmaceuticals designed specifically for an individual patient.

A Budget-Friendly Manufacturing Alternative

The medical field has been experimenting with 3D printing for more than two decades and we are now beginning to realize the full benefits. The technology offers inexpensive alternatives to traditional medical interventions. Today, 3D printed prosthetics and implants for dental, spinal, and other disorders are replacing traditional methods of manufacturing these items. It is even being used to do rapid builds of custom surgical tools to meet the specific needs of a single or multiple medical procedure.

The benefits of this ability to do mass customization to produce complex end products mean better patient interventions and healthier long-term outcomes. That’s the beauty of 3D printing. Timely production, quick alterations, customization on the fly, and one-off items. And the cost when compared to manufacturing the traditional way is significantly less meaning savings for hospitals in terms of the need to keep inventory volumes sufficient for anticipated procedures, with the items often exceeding their shelf expiry dates. And it means those cost savings can be passed on to patients making medical interventions more affordable.

Advanced Technology

3D printing has introduced bioprinting, using living cells as the ink to create tissue and organs for surgical implantation. It means instead of using donated tissues and organs, the patient’s own cells can be the building blocks to treat organ failure and reconstruction. For hospitals, the chronic shortage of transplantable organs will no longer be a problem. Instead, tissue engineering using the patient’s own stem cells combined with growth factors can produce the living ink that 3D printers can use to build a new kidney or other vital organs. Or 3D printers can apply the living ink to a scaffold made of inert materials that become the structure for tissue regeneration whether it be cartilage, bone, muscle, or blood vessels.

Full Customization

How is customization achieved? Whether it’s the use of stereolithography or other means of 3D printing, the technology has the ability to build artificial limbs and implants for clients. Prosthetics can be made within 24 hours for dental, spinal, and even hip implants. Using 3D printing implants and prosthetics solves the persistent problem for orthopedics of having an insufficient supply of generalized products for procedures. Instead, the printer offers complete customization of design that is a perfect fit for the client.

Surgical Preparation

Creating an accurate anatomical model of a patient’s heart in preparation for surgery is now possible using 3D printers that can use medical diagnostic imaging files from MRIs, CAT scans, and other radiology tools as digital sources. It gives surgeons and medical assistants a better gauge of the biological and physical makeup of the targeted organ allows for better decision-making prior to and during the performance of the procedure.

In the past 2D images from catheterization, fluoroscopy, x-rays and other types of scans formed the basis for a surgeon’s understanding of a patient’s medical status. The alternative to this was the study of the anatomy of cadavers. But finding a cadaver with the same pathology as that of the patient was next to impossible. 3D-rendered anatomical models, however, render those past methodologies obsolescent.

Enhanced Productivity

3D printing is fast. The prosthetics and implants produced this way exhibit accurate resolution and a level of accuracy not possible from milling and forging an alternative. And delivery time for the finished object is a fraction of what it would be if a manufacturer were to be asked to provide an equivalent.

Democratization and Collaboration

Finally, it should be noted that medical 3D printing brings democratization of design to medical interventions as well as an unprecedented ability for knowledge sharing among medical professionals and researchers.

The use of 3D-printing data files means what is produced can be shared allowing for faster dissemination of new knowledge and techniques within medicine. Medical practitioners and laboratory researchers can access downloadable files from open-source databases to replicate 3D-printed bio-inks, models, and devices. Since 2014, the United States National Institutes of Health have established a 3D Print Exchange to promote sharing of 3D-print files in support of biomedical science advances.