July 27, 2015 – Back in June at the DARPA Robotics Challenge, a South Korean robot named HUBO took home the $2 million US grand prize beating out 22 other robots. It was an impressive and clever adaptation of robotics that turned out to be the differentiator. The South Koreans recognized that bipedalism, the way we humans walk, is inherently unstable. In fact walking is all about controlled falling and recovery and when a robot has to do it invariably the falling gets in the way. So what the South Koreans did was put wheels on the robot’s knees to create an optional mode of movement (see image below). HUBO completed 8 tasks in 44 minutes, 28 seconds.

The South Koreans were thinking outside the box in designing a somewhat humanoid-like robot. And this is really what robotics’ future is all about, the creation of intelligent machines that don’t necessarily have to look like us and can succeed at specialized tasks or be good generalists. We can build tiny robots or ones bigger than us.

Here are some of the recent robots that made headlines.

Millibots Could Replace Surgery

In Isaac Asimov‘s Fantastic Voyage, a miniature submarine with a shrunk-down human crew is injected into a blood vessel of a scientist to ferry them to the brain of the patient in an attempt to repair an internal injury. Leave the miniaturized scientists out of the equation and you have science fiction becoming reality brought to you by researchers at University of Houston who have developed an MRI-powered millibot for minimally invasive medical procedures that can replace complicated surgery.

The team designed their robot from three tiny 3D-printed plastic components containing titanium rod spacers and two steel balls. The robot works on the same principle as a Gauss gun. If you are not familiar with this technology it was first described by Carl Friedrich Gauss. The Gauss or Coil gun uses magnetism to accelerate a projectile along a linear path. It works very much like a MAGLEV train but in this case the magnetic field of the MRI is the energy source.

The robot is injected by hypodermic needle into a patient’s body where an MRI provides both navigation and propulsion to the device. The inventors believe their millibots can be used to treat spinal cord blockages, brain injury, hydrocephalus and in procedures where therapeutic catheterizations today are the minimally invasive method of choice.

Robot Demonstrates Contingency and Adaptability Planning

Today’s industrial robots are designed for repetitive tasks. Should a part break down, the robot goes offline until repaired. But what if a robot could adapt and function even when one or more of its parts malfunction? What if the robot could instantly adapt to a changed condition or a changing environment?

That’s exactly what a six-legged robot designed by Jean-Baptiste Mouret, of INRIA in Villers-les-Nancy, France, can do. It is outfitted with software that is instantly adaptive. If one leg stops functioning the robot instinctively changes to a different walking pattern to find an acceptable means of locomotion for completing an assigned task. It does this because it has a library of 13,000 walking patterns that provide instant knowledge and adaptation capacity.

When confronted with a broken leg joint the robot experiments with varying walking patterns until one works. Instant adaptability allows the robot to respond to changes in terrain. When confronted with a freshly waxed floor the robot figured out a way to slip and slide to its objective.

The software designed for this six-legged robot can be adapted for almost any robotic device including industrial arms, the most common automation application found in factories today.

Robots with the Capacity to Learn by Doing

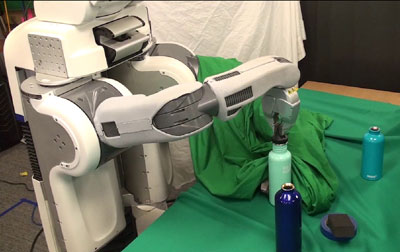

BRETT is a UC Berkeley-designed robot that figures out simple tasks in as little as 10 minutes. The robot is encoded with reinforcement learning, not task-specific programming. This deep learning lets the robot create a neural net to process the data it collects and recognize patterns within the information.

In the demonstration put on by Berkeley’s Department of Electrical Engineering and Computer Sciences, BRETT was asked to match blocks to similarly-shaped openings, as well as to stack LEGO blocks. The robot accomplished both tasks each within a few minutes.

BRETT’s software contains a reward function that keeps score on how well the robot’s movements get it closer to completing an assigned task. The score is fed back into the neural net where pattern recognition lets BRETT determine which movements produce the best results.

For a robot like BRETT the only limitation on its capacity to learn is the amount of data it can analyze and process through its neural net. That has significant implications for humans. No longer are robots only a threat to those working on repetitive assembly jobs. With a capacity to learn it is not too far fetched to predict by 2040, that more than half of all jobs we humans get paid to do will be done by robots and they won’t require remuneration.

In the picture below BRETT has learned how to screw a cap onto a water bottle.