June 28, 2017 – Companies like Nanosolar, a San Jose, California-based company, Global Photonic Energy, Bloo Solar, EnSol and Solarmer Energy, along with a number of technical institutes, are in a race to produce the first thin-film nano solar cells that can be used in multiple applications, from rooftop solar to solar appliques for mobile phones and other portable technologies. Using a range of materials from nanotech inks printed on aluminum foil to single-molecule-thick graphene sheets and lithium carbonate, or molybdenum diselenide, copper indium selenide sulfide quantum dots, graphene coated with zinc oxide nanowires, gold nanowires and nanomeshes, silver nanocubes, they are in pursuit of creating solar cells that can continuously charge devices. Some are even working with polymers and nanoparticles and wires to create cells transparent to visible light.

Using a range of materials from nanotech inks printed on aluminum foil, to single-molecule-thick graphene sheets sandwiched between lithium carbonate or molybdenum diselenide, to copper indium selenide sulfide quantum dots, graphene coated with zinc oxide nanowires, gold nanowires and nanomeshes, and silver nanocubes, university laboratories, and new ventures are hot in pursuit of creating solar cells that are malleable, inexpensive and portable for multiple uses. Some are even working with polymers with embedded nanoparticles or nanowires to create cells transparent to visible light. That means every window on a house or building can generate electricity.

At Technical University of Munich, research is being done on lightweight, flexible solar cells mated to rechargeable batteries and applied as thin film to mobile phones or tablets. The focus of TUM.solar, a research group within the University, is on nanomaterials and organic and inorganic hybrid systems to make the next generation of solar cells easily shaped and applicable to almost any form factor. This means no more is solar technology tied to rigid silicon substrates that need to be placed in frames, but rather solar appliques for portable consumer electronics, windows or even the skin of buildings and homes. These new solar power generating materials will make the dream of 100% solar power a reality.

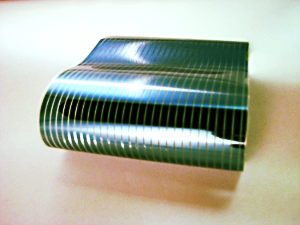

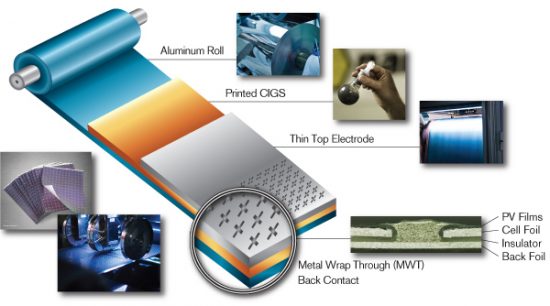

At Nanosolar, the technology uses low-cost aluminum foil and produces 17.1% efficiency in converting light to electricity. That’s comparable to current silicon-based solar panels in terms of energy output. But the Nanosolar technology has an enormous advantage. It literally can be rolled out like aluminum wrap you buy to use at home. And at two microns thick, 0.00007874015748031496 of an inch, the film can be installed on roofs, is abrasion resistant, requires no rack mounting, and adds very little weight.

Global Photonic Energy Corp, is a Trenton, New Jersey company, designing organic photovoltaic cells. Organic solar cells are ideal for covering clear surfaces because they are translucent. They also can be applied as a thin film to conform to non-flat surfaces which make them ideal as a skin put on an automobile body, mobile phone or any other portable device needing an energy source.

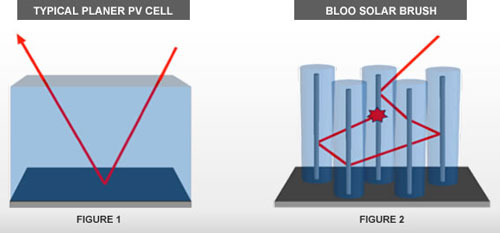

Bloo Solar Inc., recently acquired by Silva Power, is a California developer of a three-dimensional photovoltaic design called Solar Brush which uses 90% less material than silicon solar cells while generating 1.5 to 3 times the current per square centimeter of surface area. That’s because each centimeter square of the Solar Brush substrate consists of 3.9 million bristles with each a single-junction solar cell about the size of a red blood cell and capable of trapping light from all angles.

EnSol, a Norwegian company, has invented transparent solar film made of a nano composite material. The film can be applied to windows, roofing, clothing, and devices. The film is created using a process called physical vapour deposition.

Solarmer Energy develops organic photovoltaic (OPV) technology for the Wearable market. Its organic polymer layers convert light to electricity and can be manufactured in rolls in a variety of colours. The material produces high energy conversion in low light. OPV is lightweight, flexible, and non-toxic. Soon technology like this will make us all net-energy generators.