April 20, 2018 – The war I am talking about is not the one between China’s solar power industry and the rest of the world, but the one between silicon and perovskites. Silicon today dominates the solar power industry. Manufacturing at industrial scale and increasing efficiencies of cells built from silica make it the industry incumbent. But perovskites, a very common mineral, have many distinct advantages over silicon solar. These include:

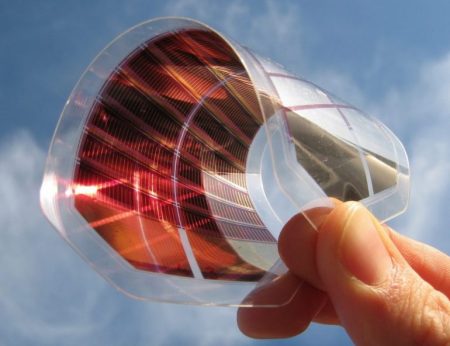

- perovskite solar cells are much thinner than silicon solar cells, and are not rigid.

- perovskite solar cells can be printed on thin flexible sheets of various sizes whereas silicon because of its rigidity is limited in the range of size that can be produced.

- the flexibility makes it possible to apply perovskite solar cells to a wide range of surfaces including the walls of buildings, (see first planned site in Poland by the European construction group, Skanska) turning the entire structure into a renewable energy generator.

- perovskite solar cells can be applied to windows emitting light to the interior while generating electricity.

- perovskites don’t have to be sourced from natural materials which often are contaminated with traces of lead; instead, they can be manufactured using commonly available industrial chemicals and metals which makes it possible to scale up production massively.

- perovskites generate electricity from a wider spectrum of light (capturing more of the blue spectrum) than silicon solar cells (more efficient in the red spectrum); that makes the former better capable of generating power even on the cloudiest days.

- perovskite solar cells can be integrated into a tandem solar cell with silicon-based products to produce up to 30% energy conversion rates, or can be built as multiple-layered exclusive perovskite tandem cells increasing energy conversion rates beyond the current single layer efficiency of around 10%. The German-based production process sees conversion rates of 36% or higher possible in tandem cells.

- perovskites can be applied as an ink to substrates in an additive manufacturing process using 3D printers.

The disadvantages to using perovskites in solar energy are quickly disappearing. The remaining ones include:

- in the natural setting, perovskites contain small amounts of lead which means the processing of the material requires lead recycling.

- perovskite solar cells in the past have tended to be less durable than silicon cells with the former showing more corrosive tendencies when exposed to the outdoor environment.

- the first production line is planned for Germany that should be open by summer. If successful the plan includes sharing the technology and licensing it to other manufacturers.

- current perovskite solar cells convert electricity at lower levels of efficiency than silicon solar cells which makes them appear less attractive than the older, established technology.

- silicon solar cells continue to see the cost of producing them drop which makes the incumbent medium harder to replace.

But perovskite made solar cells have an enormous upside with predictions that in time will see conversion to energy efficiencies exceeding the best that silicon solar cells produce.