The computing revolution described in previous blogs has as its natural outcome the potential to develop cyber intelligence that resides within a machine. Whether these machines are used to assemble material goods or are robots that roughly resemble human or other animal forms, it is clear that in the 21st century we are on a path towards this conclusion.

To understand the development of machine intelligence let’s do a quick historical review. The roots of our industrial revolution began with the creation of machines that didn’t require human power to run. Other than human or animal muscle, running water and wind were the power source for most machines prior to the 18th century. The harnessing of steam began the revolution that led to industrial manufacturing on a global scale in the 19th and 20th centuries.

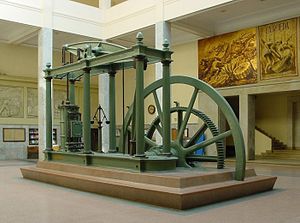

What kind of machinery are we talking about? Mechanized processes powered by steam dominated the beginnings of what we call the Industrial Revolution. Steam engines had their start in the last few years of the 17th century but came into usage by the middle of the 18th largely for use in the mining industry. Constant innovation in steam technology led to significant power breakthroughs by the end of the 18th. James Watt and Matthew Boulton perfected steam engines so that they could be used for general purposes, whether to pump water, or drive the rotary machinery of a factory or a textile mill. By the early 19th century steam engines became mobile leading to the building of steam boats and railway locomotives.

Two other developments paralleled the perfecting of steam power. These were the use of coal as a ready source of energy and the development of machine shops for the creation of machine tools. Machine tools have their origin in the world of watchmakers, the first assembly line batch producers of wheels, cogs and gears, the clock work mechanisms that we are familiar with to this day. The 19th century wars in Europe, nationalism, and the competitive pursuit of colonies played a considerable role in the perfecting of machine tools with numerous inventions of devices for the creation of interchangeable parts being the outcome. The revolution in transportation technology was a further driving factor in the creation of machine inventions. From 1860 to 1910 precision metal-working machine tools led to standardization of mass production on a global scale.

By the mid-20th century a new element had been added to machinery and manufacturing, numerical control, the automating of machine tools through the encoding of programmed instructions contained on some form of storage medium. The first numerical control manufacturing systems used punch cards to drive instructions to machines to generate metal cutouts. By creating a programmed series of instructions driven by the punch cards the manufacturing equipment could precisely cut the metal into appropriate shapes without human intervention. Punch cards were soon replaced by tape in which precision instructions were represented by punched holes. The machine would read the tape and execute the program. It was only a matter of time before hand-punched numerical control tape mechanisms were replaced by computer controls and the development of machine languages to create precise instructions for manufacturing processes.

Computer-aided design and computer numerical control have been with us ever since. These technologies are perfect for the mass production of similar products. This is what the 20th century was all about. But the 21st century is going down a new path where computer-aided design is focused on new consumption patterns leading to mass customization. We’ll talk about that in Part 2, our next blog.

Great, I didn’t know about that till now. Thanks!