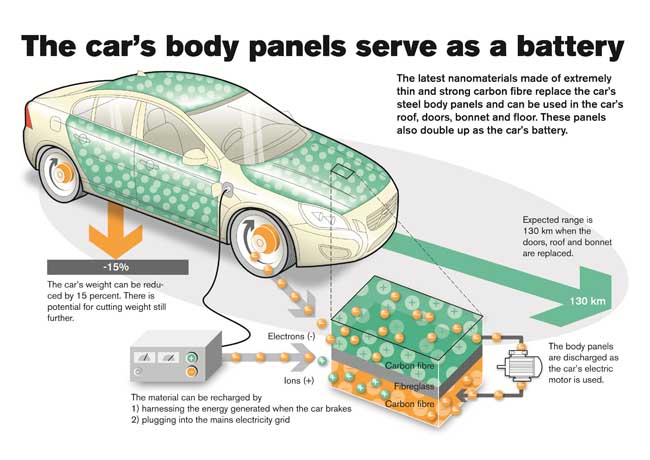

The biggest limitation for electric vehicles (EV) is the battery. Tesla, General Motors, Nissan and others install heavy batteries that limit vehicle range and performance. The batteries take up as much as 15% of the vehicle’s total weight.

So Swedish automobile maker, Volvo (now owned by China’s Geely Holding Group) decided to dispense with the battery entirely, substituting a super capacitor made from advanced carbon fiber-based nano-materials that can be integrated into the body panels of the vehicle.

Volvo has chosen the S80 model to demonstrate this concept. The vehicles side body, doors, hood and roof panels are made of nano-material (see image below) that replaces the electric batteries used by conventional EVs. The vehicle plugs in to initially charge and then recharges the supercapacitor panels during braking. A single body panel like the hood can easily supply all the energy needed to run the vehicle’s internal electronics. Additional panels can power the drive train.

Volvo has yet to get beyond building a few of the panels but it is encouraged by early tests which show that the material stores energy much faster than conventional batteries. It also delivers its charge faster.

Integrating power storage into body panels is not a new idea. The Lola B12 69/E, an electric racing car that recently set a land speed record for EVs of 328 kilometers (204 miles) per hour, incorporates super capacitors and a fully-integrated drive train within the body of the vehicle.