June 5, 2018 – Energy storage, the panacea for the renewable industry, comes in more than one form. We usually think battery packs like the PowerWall that Tesla is marketing to the world, a stack of lithium-ion cells with inverters and software controllers. But there are other ways to take generated energy from renewable and other sources and store it for a rainy day (particularly useful if you are using solar as your energy source).

I’ve written about a variety of these types of options from pumped storage that pushes water uphill to a reservoir and then releases it flow down to power turbines and generators, to compressed air stored in sealed buildings or underground impermeable reservoirs. But this new facility near Manchester is something new.

The Pilsworth Liquid Air Energy Storage (LAES) plant opens today. Developed in conjunction with The Birmingham Centre for Cryogenic Energy Storage, University of Birmingham, LAES is owned and operated by Highview Power and has a capacity of 15 Megawatts or enough electricity to serve 5,000 homes continuously for three hours. The Pilsworth facility is a pilot project. A larger plant is planned with a capacity of 50 Megawatts.

So how does LAES work?

The plant uses coolants to decrease air it takes into the system to -196 Celsius (-321 Fahrenheit) degrees. At that temperature, the air liquefies making it easy to store as a cryogenic fluid. In fluid form the air volume is dramatically decreased which makes the change of state from liquid back to air a means to exert sufficient force to drive turbines which then generate electricity.

The plant which has been built on a landfill site outside Manchester is a finalist in the United Kingdom for being the BusinessGreen Renewable Energy Project of the Year. The award is to be presented June 27, 2018.

The process is similar to that used for liquefying natural gas which involves super cooling and compressing the fossil fuel into liquid form. But instead of natural gas the fuel is ambient air. The energy sources to operate LAES can be waste heat from landfill or industrial plants, or can be off-peak period electricity generated from any power source. Regardless the energy derived is used to power conventional air conditioning absorption chillers which cool the ambient air drawn into an industrial air separation unit. For every 700 liters of ambient air, LAES creates 1 liter of liquid air which gets stored in an insulated, unpressurized tank. When heated the liquid air boils and gets converted back to 700 liters of air. The pressure exerted by this phase change from liquid to gas is used to drive a turbine connected to a generator.

The University of Birmingham is also experimenting with liquid nitrogen rather than ambient air largely because there is are existing commercial industrial sources for that gas with a transportation infrastructure to make it readily available. And because nitrogen is the most significant gas in our atmosphere (four times greater than oxygen), using it for LAES as opposed to ambient air, seems doable on a commercial operating scale.

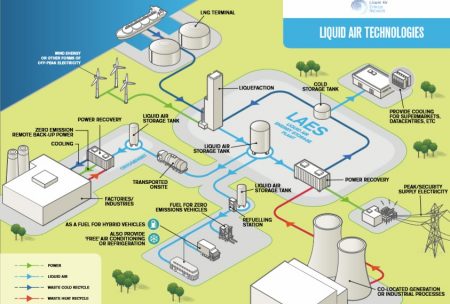

The University of Birmingham has prepared a report which can be downloaded from its site entitled “Doing Cold Smarter.” In the report, it proposes an emerging “Cold Economy.” An illustration of the various ways it believes liquid air technologies could be deployed can be seen below. It is noteworthy that the technology would produce net-zero emissions which makes it attractive in the effort to combat global climate change. To learn more watch this YouTube posted video.