April 30, 2017 – Range anxiety, recharge infrastructure. recharge time, and battery volume and weight are among the issues that continue to make electric vehicles (EVs) less attractive to the average car and truck buyer.

Lithium-ion remains the standard in EVs today. Occasionally we hear of a battery fire in a car, or recently in lithium-ion batteries in Samsung Galaxy 7 smartphones. That’s because any design flaw in a lithium-based battery could cause the material to overheat. That’s why those researching to find a better battery solutions are looking at other materials such as sulphur, aluminum and zinc.

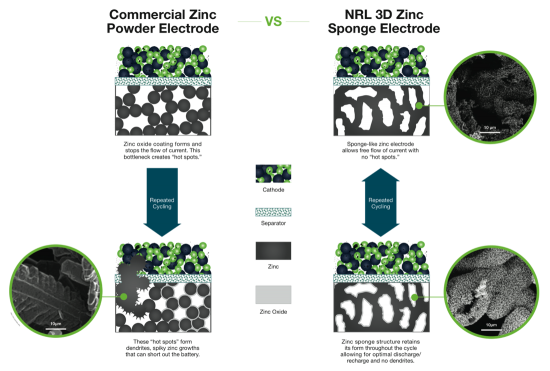

A company in California, EnZinc, is, you guessed it, developing a battery that uses zinc. You may ask why hadn’t anyone done this before? Well they have but zinc-based batteries have always failed in applications requiring significant recharge cycles. That’s because the process of making the zinc anode has produced imperfections that cause the batteries during discharge and recharge to grow long structures called dendrites. These eventually cause short circuits and battery failure.

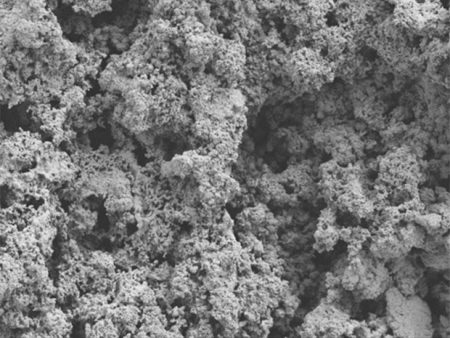

But EnZinc has solved the dendrite problem with a new manufacturing process that alters the internal structure of the zinc to suppress dendrites. The trick in the design is to create a sponge-like zinc matrix. So instead of a one-time or minimal-recharge use battery which has been the domain of zinc-based storage to date, the batteries feature discharge and recharge with no hot spots and dendrites. The image below attempts to illustrate the difference between what EnZinc has developed and traditional zinc-based batteries.

In an April 27th press release, Michael Burz, CEO of EnZinc, is quoted stating “This breakthrough in rechargeable battery technology means that zinc has the potential to displace lithium because it is a safer, more affordable, and more readily available material….Large battery-powered electronics from electric vehicles to home energy storage will be able to be powered by cleaner, fully recyclable zinc-based batteries—and they’ll carry none of the fire risk of lithium-based batteries.”

The company has worked on perfecting the manufacturing process over the last six years to produce the zinc-sponge matrix that is the technology breakthrough. It should spawn a family of batteries from ones small enough to power smartphones, and larger ones for EVs, home-power storage and grid-energy storage.

The U.S. Naval Research Laboratory (NRL) has partnered with EnZinc on developing zinc-based storage technology. Why?

States Debra Rolison, Head of Advanced Electrochemical Materials, at the NRL, “we keep having too many catastrophic news stories of lithium-ion batteries smoking, catching fire, exploding…there’ve been military platforms that have suffered severe damage because of lithium-ion battery fires.” The U.S. Navy is particularly concerned about the use of lithium-ion technology at sea. No one wants a battery fire on a submarine or ship when in operation. Lithium-ion technology is seen as too problematic. And in addition the U.S. Navy likes the fact that zinc is readily available and a lot cheaper than lithium. States Rolison, “zinc is everywhere.”

EnZinc has run experiments with a zinc-nickel combination that can withstand 50,000 discharges and recharges. That meets the requirements of EVs which operate in a start-stop manner. They have also experimented with their rechargeable battery using a Nissan Leaf EV which normally incorporates a 339 kilogram (750 pound) lithium-ion battery stack. The replacement zinc-nickel stack weighs 220 kilograms (485 pounds) and in specific energy and energy density, provided much greater watt-hours.

Burz notes that the zinc-nickel substitute battery “offers the energy of lithium-ion batteries but at the cost of lead-acid batteries.” That’s because zinc mining yields 14 million tons per year, representing the fourth-most mined material on Earth. In a U.S. Geological Survey (USGS) from 2011, zinc’s proven reserves exceeded 250 million tons. At the time the USGS noted that twice as much zinc exists in unproven reserves just in the United States alone. And unlike some minerals, zinc which is used in galvanized steel, can be completely recycled and reused. So we should never see a zinc shortage on the planet.

The U.S. Navy is also experimenting with other zinc-material combinations including zinc-silver batteries, of great interest for use in submersibles because of the higher energy output to weight.

The latest experimental results are reported in the April 28, 2017 edition of the American Association for the Advancement of Science journal.